What Is Bitumen Decanter

Bitumen decanter, also named bitumen melting machine and bitumen melter, is a facility mainly applied to melt the solid bitumen from barrels via thermal oil circulating and transferring heat. The liquid bitumen can be used for asphalt plants to produce asphalt mix, as well as other industrial purposes.

Types Of Bitumen Decanters

Actually, It's the barrel entering modes that decide the types of bitumen decanters. Different type of bitumen decanter has a different mode of drum entering the melting chamber. Plus, the time for barreled bitumen to enter the melting chamber is also one of the main factors influencing the production capacity of the equipment. There are currently 3 main barrel entering modes, so bitumen decanters can generally fall into 3 types.

1. Batch Bitumen Decanter

Place a batch of drums one by one upside down at the designated position on the tray firstly, and push the tray into the melting chamber once it's occupied fully. After decanted, the empty drums will be withdrawn from the melting chamber. This type features intermittent operation, and one batch steps up to the plate only when the previous batch is finished.

The shortcoming of this barrel entering mode is low efficiency because both actions of placing and pushing take a somewhat long time. However, the tray can be placed on a weighing device in order to inspect whether all the barrels are decanted. It also can be preset that if anyone barrel is not clean, the tray would not be pulled out.

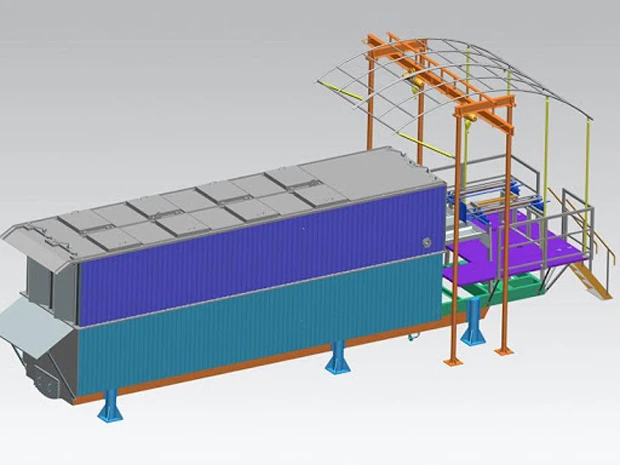

2. Crane Loading Bitumen Decanter

As opposed to the batch bitumen decanting equipment, the continuous ones are characterized by production without intervals. A barrel is moved into the melting chamber after a decanted barrel is pushed out from the outlet of the chamber. This cycle gets repeated again and again, and no intervals exist amid. Continuous bitumen decanting facilities nowadays can fall into the crane-loading type and hydraulic-loading type. Let's start with the former one.

The barrels are firstly hoisted to the position by the small crane, and then they will be pushed into the melting chamber by hydraulic thrust. Under the ideal condition, it takes 70 seconds to complete the entering action of a barrel. That is to say, up to 50 barrels can be completed in one hour, equalling 8 tons of bitumen.

There are two problems with this mode.

- The barrels must be placed under the cantilever beam, which costs some time.

- If the barrels need to be turned over manually on the ground, the labor required is too large, and the asphalt barrel is more likely to fall and deform, which will affect the running track of the barrels in the decanting equipment.

3. Hydraulic Loading Bitumen Decanter

Compared with the mode previously mentioned, this one features full reliance on hydraulic power. Just put the drums on the bottom tray of the machine, and then the oil cylinder runs, and the drums are turned and enter the melting chamber sequentially. In this way, a process can be shortened to only 20s.

How A Bitumen Decanter Works?

The working principle of the bitumen decanting machine is not complicated at all, and the specific processing procedures mainly involve heating and melting. Other auxiliary actions like hoisting the drums and store the liquid bitumen, changes with barrel entering modes, and the utility of the melted bitumen.

Working Principle of Bitumen Decanter

- Sent solid bitumen in barrels or bags into the melting chamber by using hydraulic arms or simply by pushing the tray artificially or mechanically.

- Pipelines installed in the bottom of the melting chamber carry thermal oil heated by the heater, which circulates and transfers heat to the solid bitumen.

- Solid bitumen is gradually extracted from barrels, bags, and drops down to the bitumen pool below.

- The melted bitumen will be pumped into the waiting trucks or bitumen storage tanks for future usage through the bitumen pump.

Precautions of A Bitumen Decanter

- Lay the foundation in strict accordance with the drawing, so the cart can go smoothly into the decanting machine.

- Inspect the bitumen decanter first before the first use, including the pipes, valves, etc.

- Keep the heating trough clean and ensure the outlet tube is smooth.

- Clean and paint the surface each year, and maintain the performance of the furnace and components periodically.

- Observe the heat exhaust pipe frequently, handle it when you find a leak or anything like that.