Asphalt Batch Mix Plant

- Model: LB700 ~ LB5000

- Product Capacity: 60t/h ~ 400t/h

- Highlights:

Stationary plant, batch mix, precise batching; classic model, most cost-effective, best-selling.

Brief Introduction

Asphalt batch mix plant is road surface material manufacturing equipment that features interval pauses in the course of prodiction due to its mixer. More accurate weighment, more precise dosing of cold aggregate, bitumen, filler, and other additives ensure the homogeneous final asphalt mixture. LB Series is ideal construction equipment appliable to manufacture paving material that is widely utilized in highway road construction and other civil construction. As a professional manufacturer and exporter, LYROAD Machinery is good at producing hot mix plants to clients according to their actual demands.

Technical Parameters

| Model | Capacity(Standard Conditions) | Mixer Capacity | Dust Remove Effect | Total Power | Fuel Consumption | Measurement Accuracy | |

|---|---|---|---|---|---|---|---|

| Fuel Oil | Fuel Coal | ||||||

| LB700 | 60t/h | 750kg | ≤20mg/Nm³ | 178kW | 5.5-7kg/t | 10kg/t | Aggregate: ±0.5% Filler: ±0.25% Bitumen: ±0.25% |

| LB1000 | 80t/h | 1000kg | ≤20mg/Nm³ | 285kW | 5.5-7kg/t | 10kg/t | |

| LB1200 | 100t/h | 1200kg | ≤20mg/Nm³ | 316kW | 5.5-7kg/t | 10kg/t | |

| LB1500 | 120t/h | 1500kg | ≤20mg/Nm³ | 380kW | 5.5-7kg/t | 10kg/t | |

| LB2000 | 160t/h | 2000kg | ≤20mg/Nm³ | 470kW | 5.5-7kg/t | 10kg/t | |

| LB2500 | 200t/h | 2500kg | ≤20mg/Nm³ | 547kW | 5.5-7kg/t | 10kg/t | |

| LB3000 | 240t/h | 3000kg | ≤20mg/Nm³ | 700kW | 5.5-7kg/t | 10kg/t | |

| LB4000 | 300t/h | 4000kg | ≤20mg/Nm³ | 870kW | 5.5-7kg/t | 10kg/t | |

| LB5000 | 400t/h | 5000kg | ≤20mg/Nm³ | 960kW | 5.5-7kg/t | 10kg/t | |

Advantages

Out of all types of asphalt mixing plants, asphalt batching plants are the most widely used. LB series are the most sold ones for LYROAD Machinery. Advantges of LB series hot mix plant are as follows.

Modular Structure

Modular structure, fit for container shipment, low shipment costs

Stable Performance

Batch mix, finished mixture is of good quality and steady performance

Versatile

Versatile, modified and colorful mixtures can be produced through adding dye, foam, fiber, modifier and other additives.

Clean

Two stage dust filtration systems (cyclone collector + bag house collector), minimize emission.

Easy Operation

PLC control system, auto/manual operation, easy to operate, safe and reliable.

Retrofit

Long life span, convenient for maintenance, able to be retrofit or expanded.

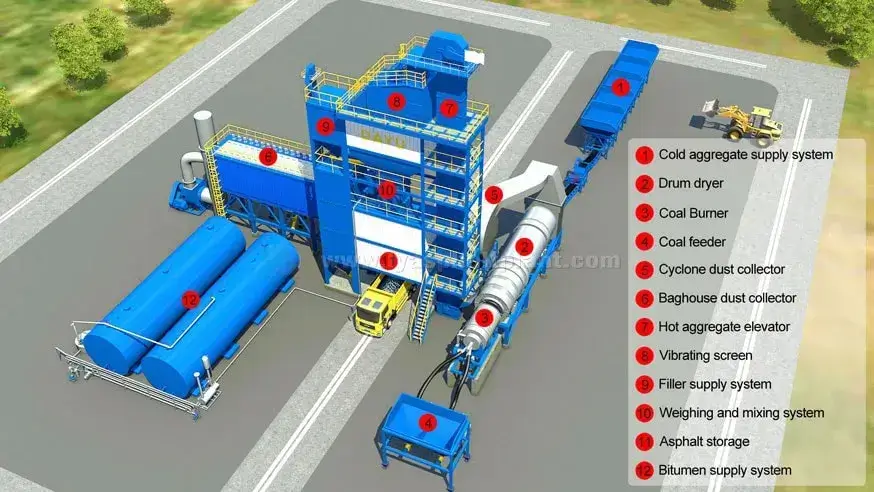

Asphalt Batching Plant Components

1. Aggregate supplying system

① Protective plates on both sides of the aggregate hoppers to avoid sundries getting into the aggregates and conveying belt;

② To make the supplying smoother, vibrators are equipped below each hopper;

③ Adds grid plate at top of each hopper to buffer the shock from aggregates flow, meanwhile it screens oversize aggregates;

④ Conveying belt is protected by dustproof cover to reduce dust emission;

⑤ Adds belt cleaners and pinch rollers to make the aggregates supplying more fluent and accurate, besides, they also extend the belt durability;

⑥ Small vibrating screen is added between belts, to further screen oversize aggregates;

⑦ The supplying system has insufficient material alarm system, ensuring a safe and smooth production.

2. Drying system

① Driving units have auto lubrication device, greatly reduces labor cost;

② Different areas inside the drying drum have different blade configurations, which can handle aggregates in different processes;

③ The rolling rings and rollers are applying high strength wear-resisting material. Deviation preventing rollers for both rolling rings;

④ The cylinder adopts boiler steel and stainless steel skin, which gives it high temperature resistance and non-deformability;

⑤ The cylinder employs thermal insulating rock wool material that can maintain the temperature inside, reducing heat loss.

3. Aggregates elevating system

① The aggregates elevator takes modular design with newest dust sealing structure;

② Elevator applies double plate link chains design, which extends the elevator's service life and reduces maintain frequency;

③ Excellent leakproofness with the moters;

④ Applies famous cycloidal pin gear speed reducers, more powerful and reliable;

⑤ The aggregates slide tunnel adopts damping structure wear-resisting plate link chains to enhance the performance.

4. Screening system

① Vibrating screens that apply world famous vibration motors are completely sealed;

② Aggregate storage bin adopts large bin structure to avoid material overflow;

③ Aggregate bins are separated by high strength wear-resisting plate to avoid aggregates mixing.

5. Weighing system

World famous brand (TOLEDO) weighment devices are adopted to make sure that the measurement error of aggregates is below 0.5%, and the measurement error of bitumen and filler is below 0.25%.

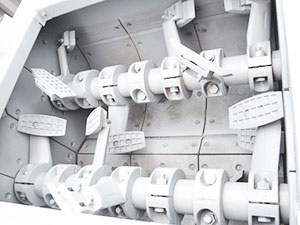

6. Mixing system

① The mixer, mixing blades and liner plates are all using the best materials with high hardness and high abrasion performance;

② The cycloidal pin gear speed reducer has better transmission efficiency and simpler structure.

7. Finished product storage system

① The storage silo has heating device to keep the temperature and quality of final mixture;

② The silo has anti-blocking device to keep asphalt quality.

8. Dust collecting system

① Double dust collecting systems, including the primary volute collector that gets rid of large size dust and secondary baghouse collector that further gets rid of the rest;

② Famous brand induced draft fan is employed, guaranteeing high efficiency yet low power comsumption.

9. Control system

① Fancy control room for operator, nice operating environment and good sound insulation effect;

② Control room is equipped with split-type air conditioner, aluminium alloy sliding windows, wood floor and so on;

③ All operations are integrated in one room, auto and semi-auto control makes it easy to operate.

How Does An Asphalt Batch Mix Plant Work?

Customer Visit

Delivery Photos

Related Equipment

Recommended articles

400+ Mixing Plants Exported

10 Design Patents

CCMA Director

Plant Exporter