Modified Bitumen Plant

- Model: GS5 ~ GS20ZS

- Product Capacity: 10 t/h ~ 20 t/h

- Highlights:

Multifuctional, intelligent control;

SBS, PE, EVA and other polymer modified bitumen.

Brief Introduction

GS series multi-purpose modified bitumen plant is designed to produce SBS, EVA, PE and other polymer modified bitumen. Roads built with polymer modified asphalt have longer service life, bigger resistance to heavy traffic load, increased skid resistance and ultra violet resistance, enhanced safety and comfort levels. GS series modified bitumen equipment is an ideal device for surface pavement of trunk road, urban road, highway, bridge and airport.

Working Process of Modified Bitumen Plant

1st Step: The hot bitumen is pumped into agitated tank at the required temperature(usually around 180ºC).

2nd Step: Thermo-plastic rubber is added to the agitated tank, and stirred for equal distribution.

3rd Step: The mixture of both is passed through the mill to physically reduce the thermo-plastic rubber particles in size by mechanical shear, being accompanied by a significant input of heat energy.

4th Step: Once the desired mixture is obtained, the polymer is pumped into modified bitumen stock tanks.

Model and Parameter

| Model | GS5 | GS10S | GS10ZS | GS10 | GS20S | GS20ZS |

|---|---|---|---|---|---|---|

| Capacity (t/h) | 10 | 10 | 10 | 10 | 20 | 20 |

| Production Mode | Batch | Continuous | Continuous | Batch | Continuous | Continuous |

| Mixing Tank Capacity (m³) | 3 | 3 | 3 | 5 | 5 | 5 |

| Colloidal Mill Feed Pump Capacity (m³/h) | 10 | 10 | 10 | 20 | 20 | 20 |

| Number of Colloidal Mills | 1 | 2 | 2 | 1 | 2 | 2 |

| Polymer Feeding Method | Manual Feeding | Automatic, Subtractive Metering | Automatic, Subtractive Metering | Manual Feeding | Automatic, Subtractive Metering | Automatic, Subtractive Metering |

| Operation Mode | Computer Operation, Semi-automatic | Computer Operation, Fully automatic | Computer Operation, Fully automatic | Computer Operation, Semi-automatic | Computer Operation, Fully automatic | Computer Operation, Fully automatic |

| Installed Power (kW) | 95 | 160 | 200 | 160 | 250 | 300 |

| Number of Containers | 40HQ*1 20GP*1 | 40HQ*2 20GP*1 | 40HQ*3 20GP*1 | 40HQ*1 20GP*1 | 40HQ*3 20GP*1 | 40HQ*4 |

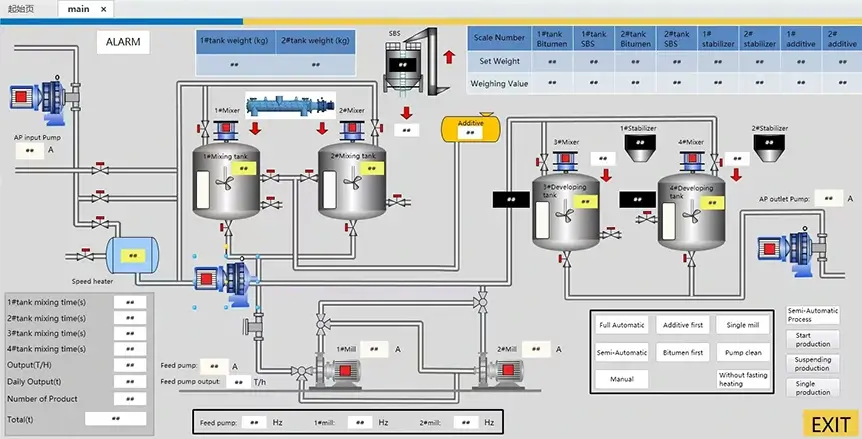

Modified Bitumen Plant Automation Control System Interface

Main Features of Modified Bitumen Plant

1. Compact and integrated structure, skid-mounted, easy for transportation and relocation.

2. Wide adaptability, it can produce SBS, EVA, PE and other polymer modified bitumen.

3. The plant adopts high-performance colloid mill, particle size after first shear and mill reaches 2-5μm; ensuring fine, homogeneous, stable and high quality modified bitumen.

4. Electronic weighing system, decrement measurement; ensuring high weighing precision and accurate material proportion.

5. Optimized heating system, blending system and piping system, saving energy cost, improving modified bitumen production rate.

6. Automatic control system, equipped with control panel,easy to operate, saving labour, safe and efficient.

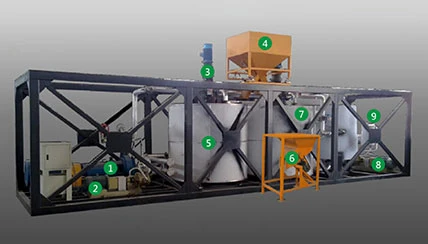

Modified Bitumen Plant Structure

1.Colloid mill

2.Pump

3.Agitator

4.Weighing hooper

5.Reaction tank

6.Modifier Crusher

7.Mixing Tank

8.Bitumen pump

9.Bitumen filter