QLB Mobile Asphalt Plant

- Model: QLB10 ~ QLB80

- Product Capacity: 10 t/h ~ 80 t/h

- Highlights:

Batch mixing, less land occupation;

Precise weighing and screening, ease of relocation

Brief Introduction

QLB series is a kind of small-sized batch mixing plant without mixing tower, transportation optimized. It output ranges from 10 ~ 80t/h, suitable for small and medium-sized road construction project which needs frequent site relocation.

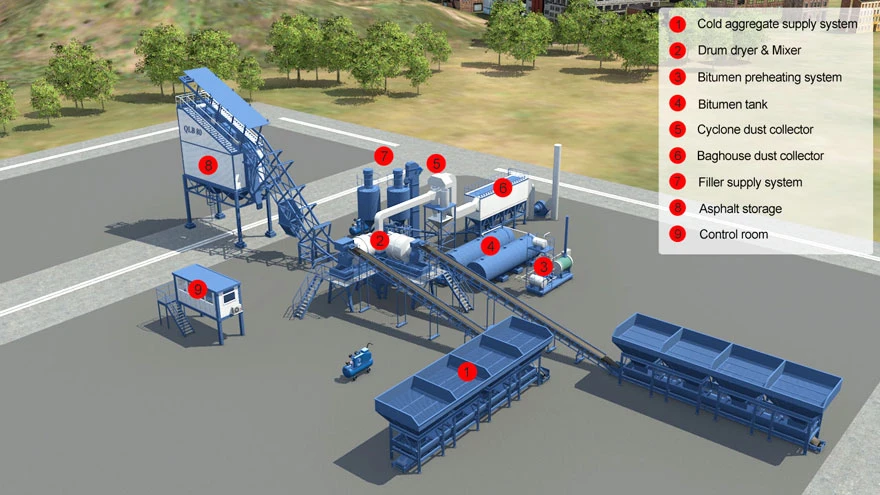

Main Structure

Model and Parameter

| Model | QLB-10 | QLB-15 | QLB-20 | QLB-30 | QLB-40 | QLB-60 | QLB-80 | |

| Capacity | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | 60t/h | 80t/h | |

| Total Power | Fuel Oil | 41.5kW | 54kW | 63.5kW | 104.5kW | 125kW | 157.5kW | 200kW |

| Fuel Coal | 57.5kW | 75kW | 86.5kW | 127.5kW | 169kW | 205kW | 276kW | |

| Aggregate Bin | 2.3m³*3 | 2.3m³*3 | 2.3m³*3 | 5m³*3 | 5m³*3 | 5m³*3 | 5m³*4 | |

| Finished Asphalt Storage Bin | 2t | 5t | 5t | 9t | 9t | 9t | 20t | |

| Asphalt Temperature | 120-180°C (adjustable) | |||||||

| Fuel Consumption | Fuel Oil: 5-7.5 kg/t; Fuel Coal: 13-15 kg/t | |||||||

| Optional Components | Water dust collector, Baghouse dust collector, Control room, Bitumen heating tank | |||||||

Main Features

1. Batch mixing plant without mixing tower, specially-designed structure, less footprint;

2. Mixing system is consisting of 1 drying drum (QLB60 and QLB80 with 2 cold feeders and two drying drums)and 1 mixer; high batching and mixing efficency;

3. Accurate measurement on aggregate,filler, bitumen and other additives, producing good quality finished asphalt;

4. PLC control sytem, ease of operation; manual / automatic operation mode.

5. Mobile chassis can be added as desired, which makes the plant mobile and ease of relocation;

6. Cold /diesel/gas burner as desired; side-mounted /bottom-mounted hot asphalt silo as desired;

7. Lower initial investment, highly cost-effective.

Delivery Photos