Bitumen Emulsion Plant

Bitumen emulsion plant is specialized equipment designed to produce emulsified bitumen by melting bitumen and dispersing resulting fine particles in water. They find extensive use in road-building projects. The final product of emulsified asphalt plants, bitumen emulsion, has a broader range of applications, such as rooftop waterproofing and pavement maintenance.

- Model: RH-6; GH-10; GJM-6~GJM-10

- Product Capacity: 6 t/h ~ 10 t/h

- Emulsion Fineness: ≤5μm, with a proportion of ≥85%

Brief Introduction

You do need a proper bitumen emulsion equipment (also called asphalt emulsion plant) if you are seeking the emulsified binders for waterproofing, asphalt road surfacing as well as road building. All of these are great applications that require asphalt emulsion. You can use it to produce it at any given time if you have one.

Bitumen emulsion is widely used in road construction and maintenance:

1. New road construction: prime coat, adhesive coat and seal coat;

2. road maintenance: fog seal, slurry seal, micro surfacing treatment, chip seal, ultra thin wearing layer, pothole rehabilitation and etc.;

3. Road pavement recycling: cold in-place recycling asphalt.

RH /GH / GJM series developed by LYROAD Machinery is an ideal equipment for bitumen emulsion production.

Model and Parameter

| Model | RH-6 | GH-10 | GJM-6 | GJM-10 |

|---|---|---|---|---|

| Production Type of Bitumen Emulsion | Ordinary Bitumen Emulsion | Ordinary and Modified Bitumen Emulsion | Ordinary and Modified Bitumen Emulsion | Ordinary and Modified Bitumen Emulsion |

| Capacity (t/h) | 6 | 10 | 6 | 10 |

| Heating Method | Thermal Oil Heating/Electric Heating | |||

| Emulsion Fineness | ≤5μm, with a proportion of ≥85% | |||

| Bitumen Content in the Finished Product (%) | Maximum Bitumen Solid Content of 55% | |||

| Bitumen Tank Capacity (m³) | 5 | 5 | 7 | 7 |

| Water Tank Capacity (m³) | 5 | 5 | 7 | 7 |

| Length (mm) | 7550 | 9000 | 11600 | 11600 |

| Soap Solution Mixing Tank Capacity (m³) | 1.3 | 1.3 | 1.3 | 1.3 |

| Finished Product Tank Capacity (m³) | 4 | 4 | 7 | 7 |

| Power Supply(V) | 380 | 380 | 380 | 380 |

| Installed Power (kW) | 30 | 50 | 50 | 70 |

| Total Weight of the Whole Machine (t) | 7 | 7.5 | 9 | 9.5 |

| Number of Containers | 40HQ*1 | 40HQ*1 | 40HQ*1 | 40HQ*1 |

| Operation Mode | Touch Screen, Semi-automatic | Touch Screen, Semi-automatic | Touch Screen, Fully Automatic | Touch Screen, Fully Automatic |

Main Features of Bitumen Emulsion Plant

1. Bitumen pump, soap pump and dosage pump (for emulsifier supply and measurement) are all driven by variable frequency motors, high precision in weighing and dosage.

2. Adopting international famous colloid mill, producing homologous, stable and reliable asphalt emulsion; clearance between rotor and stator of the colloid mill is adjustable, the min. particle size is 1μm, fit for both common and modified bitumen emulsion production.

3. Two preparation tanks take turn to produce diluted emulsifier solution, ensuring continuous production.

4. Our bitumen emulsion equipment comprises main components such as pipelines, valves, and tanks, all constructed with corrosion-resistant materials, ensuring a longer lifespan.

5. The PLC control system of our bitumen emulsion plant, supporting automatic and manual operation, easy to operate and 1 operator is enough.

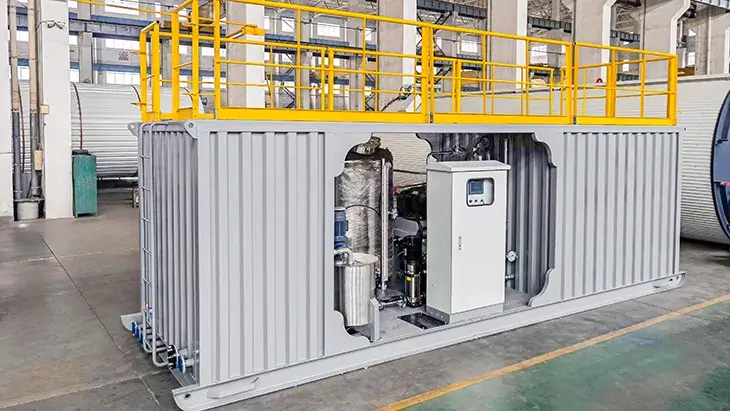

6. The whole bitumen emulsion plant is a integrated structure and can be put into container, quite easy for transportation and relocation.

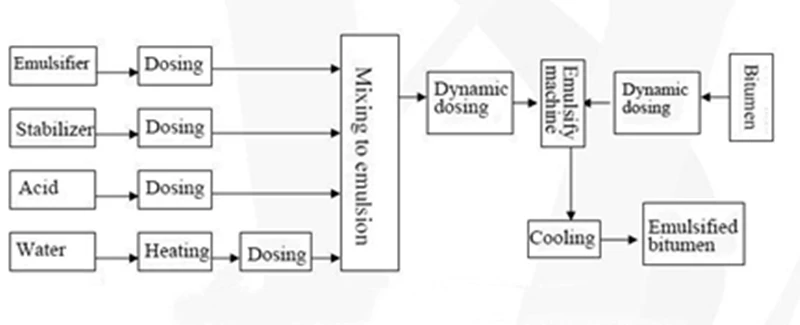

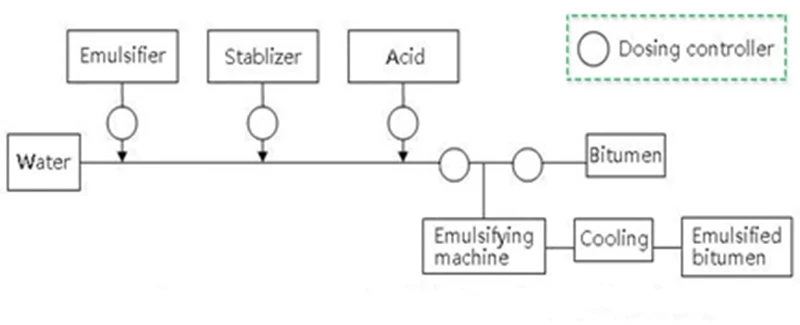

Bitumen Emulsion Plant Workflow

Detailed Information

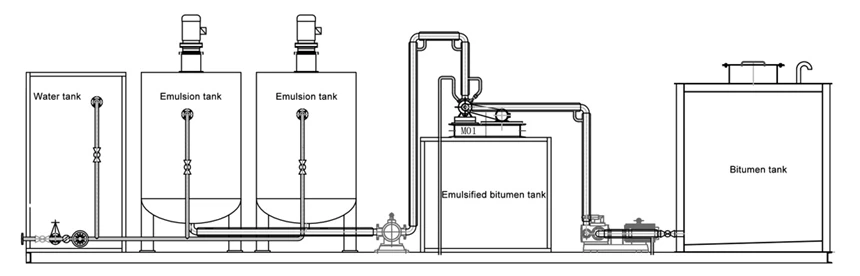

1. Clear water system

It comprises water tank, water pump, pipeline, etc.

2. Emulsion system

It is made up of emulsion tank AB, flowmeter, emulsion pump, regulating valve, etc.

3. Bitumen Supply System

It is composed of bitumen tank, bitumen pump, bitumen pipeline, etc.

4. Emulsified bitumen System

It consists of emulsifier, sampling valve, heat exchanger, etc.

5. Heat Exchange System

It comprises heat exchanger, emulsified bitumen discharge pipeline, submersible pump (or sewage pump), cooling water inlet and outlet pipeline.

6. Heat Conducting Oil System

It is a closed-circuit system with automatic temperature control. Under the action of the heat conducting oil pump, the heat conducting oil heates the parts that need to be heated, and finally returns to the heat conducting oil pump.

7. Electrical Control System

It includes two control systems: manual control and automatic control.

8. Additive System (Optional)

9. Pneumatic control system (Optional)

It uses air compressor as power source and controls five pneumatic valves (normally closed) to open and close through five solenoid valves, which facilitates the opening and closing of water injection and drainage pipelines.

Main Applications of Bitumen Emulsion Plant

RH Series Bitumen Emulsifying Machine

GJM Series Emulsified Asphalt Facility

Chip Sealing

Slurry Sealing