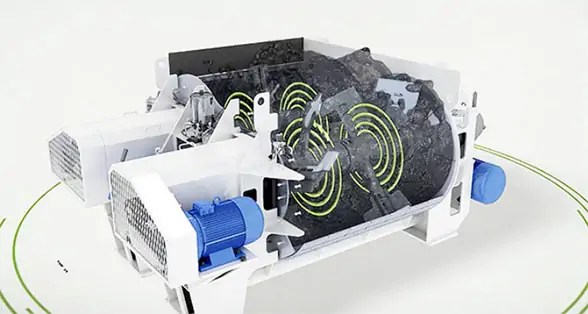

The cutting-edge and innovative vibration mixing technique uses the force of mixing and vibration synchronously to shatter the cement completely and distribute it uniformly. As hydration effect gets enhanced, interface adhesion and workability are improved and microscopic homogeneity is achieved. It ideally solve the problems with tradition mixing.

Get Price

Vibration Mixing VS Traditional Mixing

In traditional twin-shaft mixer, 10%-30% of the cement particles are not sufficiently dispersed, whereas in the vibration mixer, cement is 100% free of clots, and more solid adhesion with water and other aggregates comes into being.

Building element manufactured by traditional mixer shows a large color difference, as well as numerous air bubbles with the diameter of 2-3mm, whereas vibration mixing brings forth rare air bubbles, making the elements obviously denser and stronger.

Less Consumption, Higher Productivity And ROI

Designed To Meet High-end And Special Demands For Concrete

We have been committed to research and develop vibration mixers for more than 10 years. To date we have launched 2nd-gen update, and gained numerous patents. 1000+ vibration mixers have been applied on various mixture production plants throughout the world.

Vibration mixing technology has been successfully employed on a large scale in China, and has got widely recognized in the building materials industry during the time of a decade. Led by us, the industry standard of vibration mixing is formulated. More and more vibration mixing concrete plants are expected to apply to various large-scale key projects around china.