YHZS Mobile Concrete Batching Plant

- Model: YHZS25 ~ YHZS120

- Production Capacity: 25 m³/h ~ 120 m³/h

- Highlights:

Super mobility, Rapid assemble, Ease of use, Higher efficiency, Homogeneous output, low initial cost

Brief Introduction

Unlike stationary concrete plants, Mobile ones are specially engineered for short-term projects and those demanding the concrete producing facilities to move frequently. While they appear compact or much smaller, they combine all the functions of fixed concrete mixing plants and some remarkable highlights of their own, enabling them to be the preferences of a lot of contractors who can employ them in diverse applications. To cater to a variety of demands, the YHZS series portable batching plants that we R&D, with the average production capacities ranging from 25 m³ to 120 m³ concrete per hour, not only impose no harm on the environment but fully cover the needs for a moderate amount of premium, diversified concrete.

Parameters

| Items | YHZS25 | YHZS40 | YHZS60 | YHZS90 | YHZS120 | |

|---|---|---|---|---|---|---|

| Aggregate Bin | Volume | 5.5m³*4 | 5.5m³*4 | 11m³*2/5.5m³*4 | 5.5m³*4 | 15m³*4 |

| Motorized Pulley | Power | 11kW | 18.5kW | 37kW | ||

| Aggregate Weighing Sensor | Max.Capacity | 1000kg*4 | 2000kg*4 | |||

| Mixer | Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Motor | Power | 18.5kW | 30kW | 22kW*2 | 30kW*2 | 37kW*2 |

| Water Measuring Tank | Volume | 0.2m³ | 0.25m³ | 0.25m³ | 0.6m³ | 1.0m³ |

| Water Weighing Sensor | Max.Capacity | 500kg*3 | 1000kg*3 | |||

| Cement Measuring Bin | Volume | 0.2m³ | 0.5m³ | 0.6m³ | 0.8m³ | 1.2m³ |

| Cement Weighing Sensor | Max.Capacity | 1000kg*3 | ||||

| Air Compressor | Power | 4kW | 7.5kW | 11kW | ||

| Control Room | Dimensions | 1.8m*1.5m*2.3m | 2.3m*2m*2.3m | |||

| Control System | Model | Siemens IPC810 | ||||

| Printer | Style | 24-Bit Pin Printer | ||||

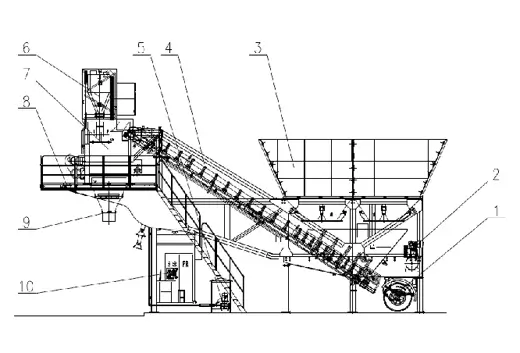

Schematic View of Main Structure

- 1. Travel Mechanism

- 2. Pneumatic System

- 3. Cold Feeder

- 4. Belt Conveyor

- 5. Water&Additive Pumping Station

- 6. Water, Powder&Additive Weighing System

- 7. Mixer

- 8. Main Structure Frame

- 9. Concrete Discharge Hopper

- 10. Control System

Advantages

Our newly launched YHZS super mobile concrete plants can be regarded as an innovative concrete production solution for small-sized projects, boasting incredible maneuverability and convenience. They are aimed to satisfy those contractors who encounter confined job sites or projects that require the device to move now and then.

Super Mobility

All components are organically integrated into one transportation trailer, making them real plug-and-go machines, and easy to transport by sea, rail and road.

Rapid Reassembly

The ingenious design allows for rapid assembly and dismantlement with minimal use of tools. Initial installation takes 3 days while reassembly only needs 1 day.

Ease of Use

Automatic operation and self-propelled fault analysis can be realized through the optimized control system, ensuring convenient running and fast maintenance.

Higher Efficiency

Apart from no or a little civil works required, cement, water, additives, and energy all can be saved owing to accurate dosing system for every component.

Homogeneous Output

Robust planetary, twin shaft mixers JS series are adopted in our mobile concrete plants in an effort to ensure high quality homogeneous concrete production.

Higher ROI

Containerized design, minimum footprint requirement, lower transportation cost, less downtime, etc., all of these make the super mobile concrete plants a profitable investment.

Detailed Features

YHZS series batching plants are characterized by ultra mobility, artful manufacturing process, and high technology, which are embedded in details, such as improved chassis, hydraulic outriggers, accurate weighing devices, full automation, etc. No foundation is needed, not some days but only hours are needed for reassembling and installation, and not much downtime is accompanied by maintenance work. These advantages make them trending building materials producing equipment currently. The lower initial cost of buying a mobile concrete batching plant will benefit you so much that it can help you get what you deserve.

①To make aggregate supplying smoother, a specific anti-block structure is adopted, ramping up the batching efficiency.

②Belt scales are mounted to ensure better accuracy through automatic compensation and inching discharge

③High dynamic accuracy measurement can be achieved thanks to the PC control, which not only helps realize fast calculating but makes the aggregate feeding process fully controllable when combined with the meter.

①Twin-shaft mixer is equipped with antomatic multi pumps lubrication system supplying grease to the four mixing shaft seals. There are virtually no grease distributor maintenance troubles, and working reliability is thus improved.

②The gearbox, discharge pump, oil level and temperature at reducer, hydraulic door opening and anto lubrication system are all under monitoring, so as to ensure normal working status.

③To guarantee long service life, along with easy maintenance, the mixer features high wear-resistance mixing blade, liner reliable shaft end sealing and lubricating system.

④A unique mixing mechanism makes quick mixing possible. Meanwhile, smooth discharge operation is enabled by an advanced hydraulic door opening system and multi-adjustable stopping positions.

①High-precision metering system is employed. For instance, water and admixture weighing adopts our unique patented technology to ensure metering accuracy.

②A high degree of automation is achieved by harnessing the renowned brand of electrical components for weighing, which benefits the dosing of the ingredients, and ensures the recipes are in line with the user's requirements.

①Top-class brand screw conveyors are utilized to deliver water, cement and additive to the weighing platform, feathered by durability, dependability, and high efficiency.

②Gradient style screw blade is the reason why block-free and stable conveying operation can be achieved.

③Running without unnecessary delay and conveying without idle stem from the scientific simulated design, which also lead to more compact cycle.

①Renowned-brand industrial computer and top-rated main electrical components enable the control to be more intelligent and more stable.

②Batching process displayed based on real-time data can be adjusted whenever necessary online. Coarse and fine aggregate batching adopts double speed courses, together with automatic compensation, providing higher accuracy.

③Two control modes-fully automatic and manual are available to switch at any time, and the whole operation becomes so easy. Plus, various safety protections help make the ease of maintenance and troubleshooting.

①Dust and noise caused during production are greatly reduced because of the fully enclosed structure of the mixer, belt conveyor, etc.

②From loading, batching, metering, feeding to the mixer, all powdery materials are carried out in isolated conditions. The final mixture is discharged to the waiting truck through an enclosed hopper as well.

③Supporting devices can be specially designed in terms of dust, noise, and waste water treatment to achieve zero pollution emission.

Recommended Articles

- Top 10 Concrete Batching Plant Manufacturers Worldwide

- How Much Does A Concrete Batching Plant Cost?