LYROAD Machinery, top bitumen decanter, bitumen drum decanter manufacturer and supplier in China, drummed/bagged/block bitumen decanter for sale, 4-10tph, best price. All these products are with CE and EAC certificate, meanwhile, a 12-month warranty is given to all our bitumen decanters. So far, we have exported a number of bitumen decanters to many countries, such as Indonesia, Sudan, Myanmar, Chad, Mali, Bangladesh, Sri Lanka, Nigeria, Kenya, Ethiopia, etc. They are becoming more and more popular overseas.

Bitumen decanter is an ideal machine to convert the solid bitumen packed in drums into liquid form by the means of heating and melting. It's often used as corollary equipment of asphalt plant for producing pavement materials.

It is often not possible to get liquid bitumen at construction sites and it also becomes difficult for you to regularly get it. Bitumen decanter is designed to heat and melt bitumen that comes in barrels and bags. It’s a perfect solution that makes sense when you want to get liquid bitumen. Our decanters fall into a drummed decanter and bagged decanter, all featuring high efficiency, reliable performance, large output, longer service life, and can absolutely satisfy your requirements.

Bitumen Decanters For Sale

New Ones For Sale (4 Listings)

Bitumen Melting Equipment DJT-3000

| Model: | DJT-3000 |

|---|---|

| Production Capacity: | 3t/h |

| Quantity of Barrels/Cycle: | 14 |

| Bitumen Storage Capacity: | 8m³ |

| Outline Size(L×W×H): | 7550×2250×2500mm |

| Delivery Time: | 10-20 Business Days |

5t/h Bitumen Decanting Machine

| Model: | DJT-5000 |

|---|---|

| Production Capacity: | 5t/h |

| Quantity of Barrels/Cycle: | 18 |

| Bitumen Storage Capacity: | 10m³ |

| Outline Size(L×W×H): | 9000×2250×2500mm |

| Delivery Time: | 10-20 Business Days |

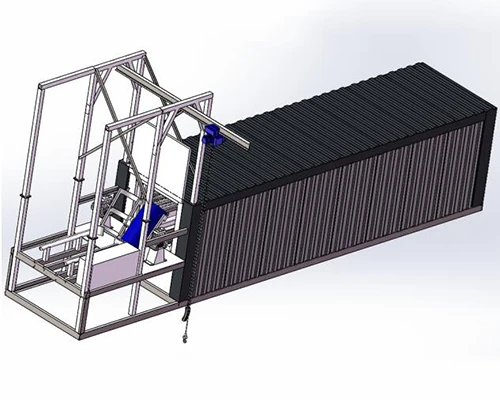

DJT-8000 Bitumen Melter With Hydraulic Drum Inverter

| Model: | DJT-8000 |

|---|---|

| Production Capacity: | 8t/h |

| Quantity of Barrels/Cycle: | 27 |

| Bitumen Storage Capacity: | 15m³ |

| Outline Size(L×W×H): | 11600×3350×2500mm |

| Delivery Time: | 15-20 Business Days |

10t/h Multi-functional Bitumen Melter

| Model: | DJT-10000 |

|---|---|

| Production Capacity: | 10t/h |

| Quantity of Barrels/Cycle: | 27 |

| Electric Hoist: | 2T |

| Thermal Oil Furnace: | 800,000 Kilocalorie |

| Delivery Time: | 15-20 Business Days |

Bitumen Decanter Price List 2021

| BEST 4 PRODUCTS | MINIMUM PRICE | MAXIMUM PRICE |

|---|---|---|

| DJT-3000 | $21,500 | $24,000 |

| DJT-5000 | $25,000 | $28,000 |

| DJT-8000 | $33,000 | $36,000 |

| DJT-10000 | $51,000 | $53,500 |

Characteristics of Bitumen Decanters

- Use hot exhaust gas (over 300℃) of burner and hot oil pipes to heat and melt bitumen simultaneously, saving energy and reducing working cost.

- The melting chamber and hot oil furnace adopt integrated structure, occupy area is small, and easy to transport.

- With turn over barrel unit, save manpower, higher working efficiency.

- Closed-construction and no pollution, friendly for environment.

- With automatic temperature & automatic bitumen level meter control system, make sure they work reliably.

- Modular integrated design, compact containerized structure, convenient and low-cost for sea shipping.

- Easy to installation, no need foundation.

- Use Italy brand burner, higher and more reliable performance.

- Easy to assembly and maintain.

Decanting Process of Bitumen Decanting Machines

Step1: Drummed or bagged bitumen has to be inserted into the decanter with the barrels being made holes on their cover. They then will be moved onto turnover device by arms that are hydraulically operated or the electrical hoist on the beam of gantry crane. Three or more rows of bitumen barrels get inside the heating zone, depending on the capacity of the drum decanter.

Step2: Surrounding the barrels is a network of pipelines that carry thermal oil. Heat transfer oil and hot emission air work together to heat the bitumen barrels. When bitumen become melted, it drops down to a melted bitumen pool.

Step3: Bitumen pump starts and pumps the liquid bitumen into waiting trucks or into another bitumen tanks.

Tips:

It usually takes approximately 60-70 minutes for bagged decanting machine to output the whole batch, then you have to place another batch of bags containing solid bitumen into the melting chamber from the top of it. Drum decanters for sale from us adopt continuous melting technology. When all the bitumen falls off the barrels, you can refill other barrels into the melting chamber regardless of whether the melted bitumen pool is empty.

Components of A Bitumen Decanter

Our drum decanters are perfectly designed so that they are maintenance free and require little attention. Anybody can operate them without much training. Some main components of bitumen decanting machine are described as below.

1. Melting Chamber

Melting chamber is fully enclosed by glass wool. Upper part holds barrels for heating, while Lower part is a melted bitumen pool.

2. Electrical Hoists or Hydraulic arms

Whatever they are, they will help in pushing the barrels into the melting chamber.

3. Thermal Oil Heater

Thermal oil is heated by the thermal oil heater and then circulate into the melting chamber, transferring heat to melt solid bitumen.

4. Pipelines

Seamless pipelines carry the thermal oil from the heater to the heating unit.

Export Cases

1. DJT-10000 Bagged Decanter Loaded On the Transport Vehicle and Left for Zambia

2. DJT-10000 Drummed Decanting Machine Will Be Sent to Indonesia

3. DJT-5000 Bagged Asphalt Decanter Shipped to Uganda

4. DJT-5000 Bitumen Decanter Ready to Run Towards Central African Republic

5. DJT-3000 Drummed Decanter Left Factory For Uzbekistan

It's not just those countries, our decanters also show their presence in countries like Myanmar, Nigeria, Namibia, Bangladesh, Tanzania, Zambia, Mozambique, Mongolia,etc. Such reliable products from the most trustworthy manufacturer and supplier with a competitive price have become increasingly salable worldwide. Once you trigger a quotation or a inquiry about our products, you would enjoy our considerate and thoughtful customer service. We are always here, 24*7, ready to satisfy your needs whenever possible.