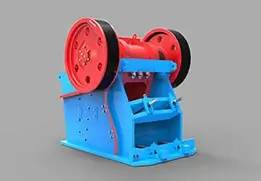

Mobile Crawler Jaw Crusher

- Model: AMJ750

- Product Capacity: 150t/h ~ 250t/h

- Significant Highlights:

1. Crawler Type

2. Track-mounted

3. Hydraulic Powered

Brief Introduction

AMJ Series is track-mounted mobile jaw crusher which works independently or with other mobile crushing equipment of our company. AMJ mobile crawler jaw crusher is featured by intelligent control, high mobility and cost-effectiveness, ideal for primary crushing .

AMJ mobile crawler jaw crushers are mainly used for aggregate and sand and other production, mining, metallurgy, quarry, construction waste crushing and the like. The jaw crusher is single toggle type which crush materials with compressive strength lower than 320Mpa. AMJ mobile crawler jaw crusher is mainly used for primary/coarse crushing.

Workshop for Mobile Crawler Jaw Crusher

Product Parameters

| Model | AMJ750 |

|---|---|

| Feeding Device | |

| Feed Height (mm) | 3750 |

| Max. Feed Size (mm) | 600 |

| Length×Width (mm) | 4300×1000 |

| Vibration Motor Power (kW) | 12 |

| Hopper Volume (m³) | 4.5 |

| Tipper Hopper Volume (m³)(Optional) | 6 |

| Crusher | |

| Jaw Crusher | ME106 |

| Feed Port Length×Width (mm) | 1060×750 |

| Weight (t) | 17 |

| Max. Feed Size (mm) | 600 |

| Crusher Power (kW) | 110kW-6 |

| Main Belt Conveyor | |

| Width(mm) | B1100 |

| Stockpiling Height (mm) | 3570 |

| Geared motor Power (kW) | 15 |

| Tail Belt Conveyor(Optional) | |

| Width(mm) | B650 |

| Geared motor Power (kW) | 3 |

| Iron Separator(Optional) | |

| Length×Width (mm) | 1900×B800 |

| Geared motor Power (kW) | 3 |

| Overview | |

| Generator Set Power (kW) | 300kW |

| Crawler Chassis | DL375A |

| Track Drive Power (kW) | 55kW |

| Total Weight (t) | ≈47T-50T |

| Processing Capacity (t/h) | 150-250t/h |

| Total Operating Power (kW) | 142 |

| Operating Dimensions (L*W*H/mm) | 15000×4960×3950 |

| Transport Dimensions (L*W*H/mm) | 15000×3300×3750 |

Main Feature

1. Robust modular structure, easy spare parts replacement, fatigue and shock resistant, longer service time.

2. Specially-designed cavity, V-shape symmetrical crushing cavity, smaller locking angle, deeper cavity, larger stroke length. Larger productivity, less energy consumption.

3. Optimized movable jaw assembly with forged heavy-duty eccentric shaft and high quality spherical roller bearings. Designed and machined on the basis of finite element analysis, stable and reliable performance. Movable jaws with perfect seal and lubrication.

4. Large crushing ratio, finish aggregate of uniform and better granular shape.

5. Highly compacted, drive motors are integrated on main frame so that the machine is smaller in size yet much more flexible.

6. Intelligent wireless controller, track-mounted, self-propelled, easy load on lowbed semitrailer, fast mobilization and relocation.

7. World famous key devices are employed, Schneider electrical elements, Cummins diesel engine, Eaton hydraulic plunger pump, Strickland track, Bonfiglioli /Brevini hydraulic motor. Performance, service life and value of the crusher is guaranteed.

Main Components

①Foldable.

②Self-locking.

③Simple and fast loading.

④Safe initial operation.

①Easy to observe and operate for all components.

②Easy to maintain and clean.

①OEM from China top manufacturer.

②Quality and performance guaranteed.

Bring oversized grains back to the feeding unit and make them crushed again.

A platform is provided to help gain access to the crusher and the powerpack, and do inspection and maintenance work.

Integrated belt conveyor, folding, hydraulic control.

All components and functions can be controlled easily via this hand-hold remote controller.

①British STRICKLAND track.

②Sturdy, stable and durable.

③Allow equipment to move flexibly at the jobsite.

Construction Case

Crawler Impact Crusher Plant AMI1213 +Crawler Mobile Screening Plant AM3600H , Mainly Process Concrete Blocks, Output More Than 100m³/h

Crawler Impact Crusher Plant AMI1213-A + Crawler Mobile Screening Plant AM3600H, A Classic Combination, 200t/h Pebble Processing Capacity

Fully Hydraulic Crawler Cone Crusher Plant AMC300 + Crawler Mobile Screening Plant AM3600H, A Most Preferred Combination With Strong Processing Performance

A Combination Consisting Of Crawler Cone Crusher Plant and Crawler Mobile Screening Plant, 120t/h Pebble Processing Capacity