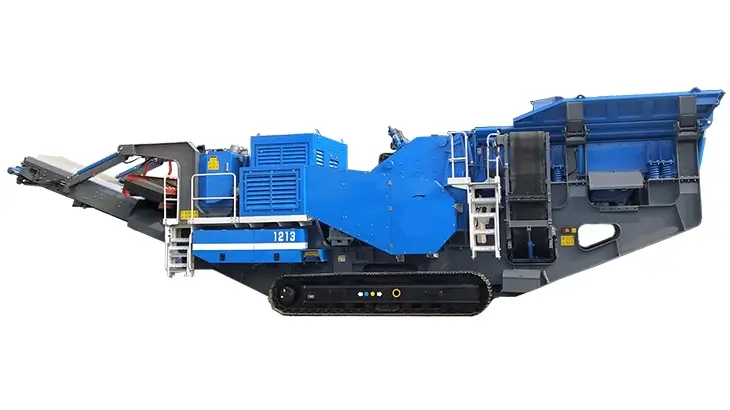

Mobile Crawler Impact Crusher

- Model: AMI1213 ~ AMI1213A

- Product Capacity: 150t/h ~ 250t/h

- Significant Highlights:

1. Modular Design

2. Intelligent Control

3. High Mobility and Cost-effectiveness

Brief Introduction

AMI series mobile impact crusher plant is featured by sturdy structure, high fatigue resistance, and excellent impact resistance. it is suited to be used for secondary crushing of soft and medium-hard natural stone and construction waste.

AMI series mobile crawler impact crusher plant applies the currently world-leading impact crusher. Overall structure, materials selected, manufacturing process, assembly methods, and other aspects of the plants have been specially optimized or designed, enabling it to enjoy many unpreparable advantages, such as distinctive structure, reliable operation, large production capacity, and small output grain size, etc.It’s ideal for secondary crushing of rocks with high hardness and abrasion.

Workshop for Mobile Crawler Impact Crusher

Product Parameters

| Model | 1213A(Two-layer Vibrating Screen) | 1213(No Aggregate Return System) |

|---|---|---|

| Feeding Device | ||

| Feed Capacity (t/h) | 400 | 400 |

| Feed Height (mm) | 3700 | 3700 |

| Max. Feeding Size (mm) | 750 | 750 |

| Feed Power (kW) | 15 | 15 |

| Hopper Volume (m³) | 4.5 | 4.5 |

| Tipper Hopper Volume (m³)(Optional) | 6 | 6 |

| Crusher | ||

| Impact Crusher | XC1213 | XC1213 |

| Feeding Port Size (mm) | 1200*870 | 1200*870 |

| Triangular Belt | 8V-8 slot | 8V-8 slot |

| Belt Pulley of Crusher (mm) | 1100 | 1100 |

| Belt Pulley of Motor (mm) | 430 | 430 |

| Discharge Port Adjustment Range (mm) | 30-125 | 30-125 |

| Max. Feed Size (mm) | 400 | 400 |

| Crusher Power (kW) | 250kW-4 | 250kW-4 |

| Main Belt Conveyor | ||

| Width(mm) | B1000 | B1000 |

| Discharge Height (mm) | 3900 | 3900 |

| Geared motor Power (kW) | 7.5*2 | 7.5*2 |

| Fine Aggregate Belt Conveyor | ||

| Width(mm) | B1200 | / |

| Geared motor Power (kW) | 11 | / |

| Discharge Height (mm) | 3000 | / |

| Return Belt Conveyor | ||

| Width(mm) | B500 | / |

| Electric Roller Power (kW) | 5.5 | / |

| Second Layer Belt Conveyor | ||

| Width(mm) | B650 | / |

| Electric roller Power (kW) | 7.5 | / |

| Discharge Height (mm) | 3340 | / |

| Tail Belt Conveyor(Optional) | ||

| Width(mm) | B500 | B500 |

| Electric roller Power (kW) | 5.5 | 5.5 |

| Discharge Height (mm) | 3200 | 3200 |

| Collecting Belt | ||

| Width(mm) | B500 | / |

| Electric roller Power (kW) | 3 | / |

| Vibrating Screen | ||

| Model | 2YA1850 | / |

| Power (kW) | 15 | / |

| Track Drive Device | ||

| Power (kW) | 55kW | 55kW |

| Iron Separator(Optional) | ||

| Length×Width (mm) | 1900×B800 | 1900×B800 |

| Power (kW) | 3 | 3 |

| Overview | ||

| Generator Set Power (kW) | 400kW | 400kW |

| Crawler Chassis | DL425X | DL425X |

| Total Track Drive Power(kW) | 55kW | 55kW |

| Total Weight (t) | ≈55T-60t | 51t |

| Processing Capacity (t/h) | 150-250 | 150-250 |

| Total Operating Power (kW) | 330.5kW | 288.5kW |

| Operating Dimensions (L*W*H/mm) | 18400×11830×4870 | 16000×3500×4125 |

| Transport Dimensions (L*W*H/mm) | 18600×3750×3780 | 16000×3500×3780 |

Description

1. The processing capacity of the crusher is related to stone hardness, feed grain size, and discharge grain size.

2. Standard configuration: manual control, wireless remote control.

3. Optional: return system, foldable side conveyor belt, iron seperator, dust-removal spraying system, belt conveyor hood, pre-screening system.

Main Features

1. Modular design, sturdy structure, higher fatigue resistance and stronger impact resistance.

2. The crusher case can be turned over for easier maintenance; Square handle bolts are employed to make the equipment more impact-resistant and wear-resistant.

3. Large feed opening, high crushing chamber, suitable for crushing high hardness and large block materials. Power consumption upon crushing suspended materials is much lower.

4. Well-designed hammerhead boasts a large impact force. Hammer shafts are adjustable, leading to a long service life of the hammerhead.

5. The grid size is adjustable, and the product particle size is accordingly controllable. Moreover, the product particles are output in good shape.

6. It comes with comprehensive crushing function, including impact, impact, collision (stones hitting each other), achieving high production efficiency, low wear of machine parts, and significant comprehensive benefits.

7. It adopts an intelligent wireless remote control device and walks on its own crawler. It can be operated by a single person remotely to get on and off the ordinary flatbed trailer to realize rapid relocation.

8. Word famous key devices are employed, Strickland track, Bonfiglioli /Brevini/Eaton drive motor, Cummins diesel engine, Schneider electrical elements, Eaton hydraulic plunger pump, Eaton hydraulic motor on belt conveyor and feeder, Omron remote controller, etc. Performance, service life and value of the crusher is guaranteed.

9. The pre-screening system can be chosen to mount and make screening function more comprehensive and excellent.

Main Components

①Foldable.

②Self-locking.

③Simple and fast loading.

④Safe initial operation.

①Easy to observe and operate for all components.

②Easy to maintain and clean.

①Fast fault diagnosis.

②Convenient and intuitive operation.

Bring oversized grains back to the feeding unit and make them crushed again.

A platform is provided to help gain access to the crusher and the powerpack, and do inspection and maintenance work.

Integrated belt conveyor, folding, hydraulic control.

All components and functions can be controlled easily via this hand-hold remote controller.

①British STRICKLAND track.

②Sturdy, stable and durable.

③Allow equipment to move flexibly at the jobsite.

Construction Case

Crawler Impact Crusher Plant AMI1213 +Crawler Mobile Screening Plant AM3600H , Mainly Process Concrete Blocks, Output More Than 100m³/h

Crawler Impact Crusher Plant AMI1213-A + Crawler Mobile Screening Plant AM3600H, A Classic Combination, 200t/h Pebble Processing Capacity

Fully Hydraulic Crawler Cone Crusher Plant AMC300 + Crawler Mobile Screening Plant AM3600H, A Most Preferred Combination With Strong Processing Performance

A Combination Consisting Of Crawler Cone Crusher Plant and Crawler Mobile Screening Plant, 120t/h Pebble Processing Capacity