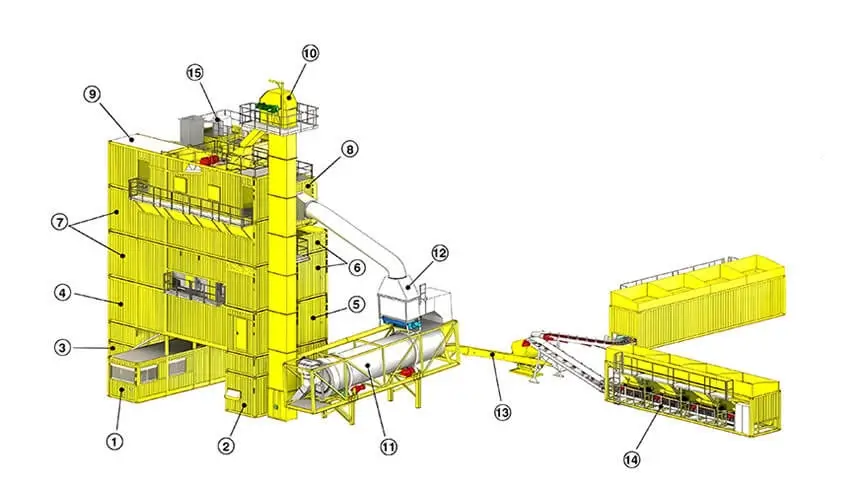

Containerized Asphalt Mixing Plant

- Model: CFB80 ~ CFB400

- Product Capacity: 80t/h ~ 400t/h

- Highlights:

1. Containerized, easy transportation

2. Foundation-free, quick installation

3. Accurate weighing, batch mix, high-quality outputs

4. Long service life, high resale value

Brief Introduction

A Containerized Asphalt Mixing Plant is a portable asphalt batching plant with a modular design, featuring convenient transportation, quick installation, and flexibility. It can effectively mix various asphalt mixtures with cold aggregate feeding system, drying system, screening and mixing system, dust collecting system, and control system through intelligent operation. The containerized design makes it easy to use the plant on different sites, providing convenience for road construction while reducing transportation and installation costs. The CFB series Containerized Asphalt Mixing Plant offers various production capacity models to meet diverse customer requirements.

Technical Parameters

| Model | CFB80 | CFB120 | CFB160 | CFB240 | CFB320 | CFB400 | |

|---|---|---|---|---|---|---|---|

| Capacity (t/h) | 80 | 120 | 160 | 240 | 320 | 400 | |

| Power (kW) | 245 | 305 | 345 | 505 | 660 | 810 | |

| Cold Aggregate Feeders (m³) | 4 x 8 | 4 x 9 | 5 x 9 | 6 x 12 | 6 x 15 | 6 x 18 | |

| Drying Drum (mm) | 6000 x 1500 | 7500 x 1600 | 7500 x 1800 | 8500 x 2000 | 9500 x 2200 | 11000 x 2700 | |

| Hot Aggregate Storage Bins (m³) | 12 | 22 | 36 | 53 | 53 | 70 | |

| Weighing Sensor (kg) | Hot Aggregate | 1000 | 1200 | 1750 | 2250 | 3000 | 4000 |

| Filler | 100 | 250 | 250 | 250 | 400 | 600 | |

| Bitumen | 100 | 200 | 200 | 200 | 400 | 600 | |

| Mixer Capacity (kg) | 1500 | 1500 | 2250 | 3500 | 4250 | 5500 | |

| Bag-house Dust Collector Filtering Area (m²) | 400 | 473 | 489 | 674 | 830 | 1132 | |

| Filler Silo (m³) | 30 | 30 | 30 | 30 | 52 | 75 | |

Advantages

A high-efficiency and high-capacity feature characterizes the containerized asphalt mixing plant. The CFB series containerized asphalt mixing plant eliminates the need for packaging, allowing easy transportation, and ensuring convenience and speed.

Foundation-Free

Containerized design, CFB series containerized batching plant main building without foundation, quick installation and disassembly

BV Classification Society Certification

Certified by BV Classification Society, ensuring safety and reliability

German Screening Technology

The vibration screening technology with a 110-year history originating from Germany is characterized by efficient screening, low energy consumption, and durability

Dust Emission <20mg/Nm³

Dual-stage dust collector, dust emission in exhaust <20mg/Nm³, environmentally-friendly

Safety Interlock Device

The built-in staircase and safety interlock device provide excellent protection for the personal safety of maintenance operators

High Resale Value

Internationally renowned brand components within the container minimize wear and tear and ensure a long service life, maintaining a high resale value

Containrized Asphalt Mixing Plant Components

1. Cold Aggregate Feeding System

① Controlled by a frequency converter, allowing stepless variable speed adjustment to enhance efficiency and reduce energy consumption;

② Equipped with sidewall belt to prevent aggregate spillage;

③ Features a sand bin moisture-proof device and bin wall vibrators to ensure a smooth material discharge process and prevent bin blockage;

④ Each feeding belt's output can be individually and automatically adjusted, ensuring precise cold aggregate batching;

⑤ Automatic aggregate shortage alarms are used for enhanced efficiency;

⑥ Emergency stop pull switch to prevent further damage.

2. Drying System

① Original patented design imported, aggregates zoning heating for high heating efficiency;

② Equipped with an automatic lubrication device to reduce labor costs;

③ Riding rings are made of highly wear-resistant materials for longer service life;

④ Rock wool insulation equipped to prevent heat loss.

3. Aggregates Elevating System

① Double pitch roller chain is made of wear-resistant material, sturdy and durable;

② Hoppers come with wear-resistant edge;

③ Inlet and outlet come with special wear-resistant device;

④ Driven by gear motor with brake, more reliable and precise;

⑤ Anti-reverse device ensures smooth running;

⑥ Sealed design with perfect air tightness, no dust leakage;

⑦ Manhole and adjustment device at bottom, easy for installation and maintenance.

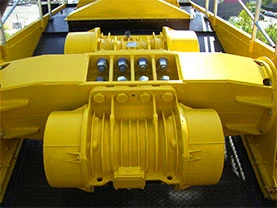

4. Vibrating and Screening System

① Vibrating screen technology originating from Germany with 110 years of history;

② Driven by two vibration motors, preventing resonance, with adjustable amplitude and frequency;

③ Equipped with highly wear-resistant screening plates to prevent aggregate mixing;

④ Specially designed feed chute, wear-resistant, and minimal noise;

⑤ Wire-meshes are made of special spring steel with anti-wear property.

5. Hot Aggregate Temporary Storage System

① Equipped with capacitive continuous level sensors to ensure high-precision measurement;

② Includes a 100mm thick rock wool insulation layer to prevent heat loss;

③ Equipped with a bypass hopper.

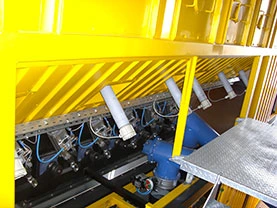

6. Weighing and Mixing System

① Each system is equipped with a weighing sensor to achieve precise measurement, ensuring accurate proportioning;

② Three-dimensional mixing, with aggregates flipping vertically, results in a more uniform mixing;

③ Swiss-formulated wear-resistant materials and multiple protective measures contribute to a long service life;

④ European technology mixer, an efficient mixing system that reduces power consumption;

⑤ The drive motor employs an automatic lubrication system, free of maintenance.

7. Finished Products Storage System

① Bottom-type finished products storage bin is convenient for discharging and transportation;

② Insulation device is equipped to ensure the asphalt quality.

8. Dust Collecting System

① Adopted a two-stage dust collecting system: the first stage employs gravity dust collector and the second stage utilizes reverse-air bag-house dust collector, ensuring high dust-collecting efficiency;

② The dust collecting system is located on the upper of the mixing tower, saving ground area;

③ The two-stage dust collecting system achieves a dust emission of ≤20 mg/Nm³, which is lower than the international industrial facility dust emission average of 30 mg/Nm³;

④ Equipped with a recycled filler storage container to minimize pollution.

9. Control System

① Containerized control room is sound-proof and heat-proof, providing comfortable environment;

② Advanced control system ensures accurate and fast operation;

③ Electrical components, including switch cabinets, circuit breakers, PLC, cables, buttons, etc., are all from well-known brands, ensuring safety and reliability;

④ Easily switch between automatic, semi-automatic, and manual modes at any time, providing simple and user-friendly operation.

How to Install CFB Series Containerized Asphalt Mixing Plant?

Related Equipment

Recommended articles

400+ Mixing Plants Exported

10 Design Patents

CCMA Director

Plant Exporter