Why Choose Us?

It is a significant decision for you to buy a hot mix plant, but it is more important to choose a reliable manufacturer. LYROAD Machinery, a trustworthy China road construction machine manufacturer, has so many special competitive advantages that it attracts more and more overseas customers to seek cooperation.

CONTENTS

Advantage 1: 20 Years' Experience, Member of CCMA

We have been insisting on road construction equipment manufacture for 20 years. During this period, we research and develop new products continuously, improve our sales service persistently. We have achieved leader status in China’s road construction equipment industry, thanks to so many years'technical innovation and market exploitation.

In 2018, we were elected as the board member of the first council of CCMA (China Construction Machinery Industry Association).

Please click the article Tips for buying asphalt plants from China to learn about the huge difference between real manufacturer and trade company. Note that you will take some risks if you choose to cooperate with trade company.

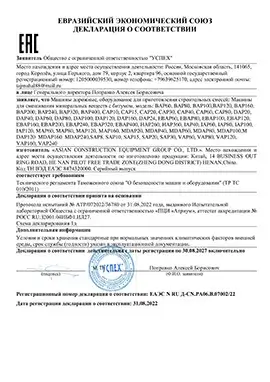

Advantage 2: Over 60 Models, With CE and EAC Certificate

As a leader in China's road construction machinery industry, we have been dedicated to research and produce a full range of asphalt mixing plants for more than 20 years. Our products have passed ISO9001, ISO14001, CE, EAC quality management system certifications.

Products that Cover All Series and Capacities

Our products have involved 13 series, over 60 models, and can meet various working conditions of customers all over the world. The following are several main series of our asphalt plant.

1. Asphalt Plant LB Series

Features: 60-400t/h capacity, batch mixing, modular design, precise screening, accurate measurement, filler and additives can be fed, dual-shaft mixer, PLC system, two stage dust collector, fit for highway, trunk road and subtrunk road

2. Asphalt Plant ELB Series

Features: 60-400t/h capacity, batch mixing, modular design, precise screening, accurate weighing, filler and additives can be fed, dual-shaft mixer, PLC system, two stage dust collector, enclosed mixing tower with lock, minimal dust emission and low noise, clean production, fit for highway, trunk road and subtrunk road

3. Asphalt Plant DHB Series

Features: 40-100t/h capacity, drum mixing, compact structure, less land footprint, convenient for transportation and relocation, drying and mixing drum integrated design, low initial investment, fit for country and local road, fit for road maintenance

4. Asphalt Plant YLB Series

Features: 60-160t/h capacity, batch mixing, modular design, precise screening, accurate weighing, optional feed for filler and additives, dual-shaft mixer, PLC system, mobile chassis, convenient for relocation, less land occupation, independent distribution cabinet, fit for highway, trunk road and subtrunk road

5. Asphalt Plant QLB Series

Features:10-80t/h capacity, batch mixing, accurate weighing, equipped with trailer and chassis, easy for transportation and relocation, two stage dust collector, filler and additives can be fed, PLC system, mixing system consisting of 2 drying drum and 1 mixer, simple structure, Less land occupation, low initial cost, fit for small and medium-sized country and local road, fit for road maintenance

6. Asphalt Plant RLB Series

Features: 60-160t/h capacity, batch mixing, accurate weighing, RAP processing device, RAP proportion up to 50%, saving fuel, multi-stage dust collecting system, PLC system, fit for country and local road, fit for road maintenance

7. Asphalt Plant JNW Series

Features: 180-240t/h capacity, batch mixing, precise screening, synchronized decrement weighing method, PLC system, two stage dust collector, no overflowed hot aggregate during production, enclosed production process, minimal dust and pollutant emission, batch cycle time reduced to 40s, 15% more productive than that of same model batch mixing plant, fit for highway, trunk road and subtrunk road

8. Asphalt Plant JJW Series

This one is a milestone product in asphalt plant industry and we launched it in 2018. It ingeniously uses vertical drying tower instead of traditional drying drum. Meanwhile it adopts synchronized decrement weighing method, one of our patented technologies, minimizing the "oil-stone ratio" deviation, eliminating overflowed hot aggregates, leading to actual dynamic accuracy within 1%.

In addition, it enjoys great advantages of operation cost control, resource saving, clean production and 260-360t/h large capacity.

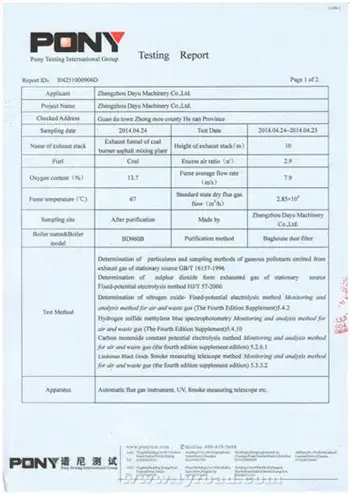

Certificates that Prove Our Strength

More than 200 highly skilled and educated employees manufacture products in a modern factory, which incorporates C.A.D.(Computer Aided Design), C.A.M.(Computer Aided Manufacturing) and C.N.C. (Computer Numeric Controlled) manufacturing techniques. Quality management system follow ISO9001/ISO14001, and our products are with CE and EAC certificate.

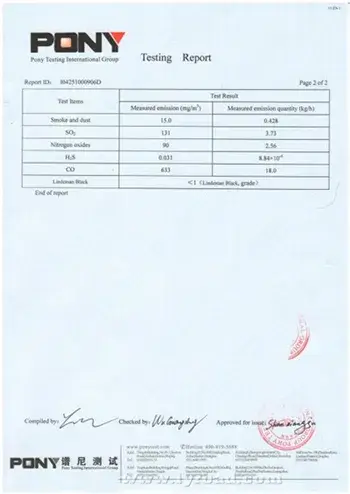

Our asphalt plants completely meet international environmental standards. In 2014, we commissioned PONY Testing Group, a well-known third-party large-scale comprehensive testing organization in China to conduct environmental monitoring on all aspects of our products. The test report with international credibility shows that the smoke and dust emission of our asphalt plants is 15.0ug/m³, lower than the international standard of 20ug/m³.

For more information about environmental-friendly features of our asphalt plants, please browse the article Highlights of environmental-friendly asphalt mixing plants manufactured by LYROAD Machinery.

Advantage 3: 400 Sets of Asphalt Plants, Over 80 Countries

We began to develop overseas markets in 2006, and have built up an experienced and skilled sale team by now. The professional team supply sales service to the world in major languages, such as English, Russian, Spanish, Arabic,etc. so you can communicate with us in your native language without any problem.

In 2017, our overseas sales reached 14 million US dollar, and the export volume of asphalt mixing plants ranks first among all of China asphalt plant manufacturers.

By far we have exported 400 sets of asphalt plants to over 80 countries and regions.

Here are some photos showing customers from different countries visited our factory.

Our customers scatter in Poland, Rumania, Russia, Australia, New Zealand, Canada, Panama, Ecuador, Peru, Chile, Algeria, Kenya, South Africa, Zimbabwe, Philippines, Indonesia, Kazakhstan, Mongolia, Egypt, etc.

We also has established branches and signed agents in dozens of countries, including Indonesia, Thailand, Russia and Algeria, so that customers all over the world can buy our asphalt plants conveniently.

The below are A few of successful cases.

There are so many successful cases that our asphalt plants are erected and run well overseas. You can click here if you’d like to see more pictures and information.

Advantage 4: Fast, Professional, Worry-free, Thoughtful Service

We take customer's satisfaction as our service tenet, provide the customers with high quality, competitive prices of products and excellent, thoughtful and fast service.

During pre-sales period, we will guide customers to choose the most suitable asphalt plant and figure out a professional investment solution. When the order is placed, we will arrange production as per requirement written in the contact, monitor the production schedule to ensure punctual delivery. After sales, we will assist customer with customs clearance process, and at the same time sent technicians to install and commission asphalt plant, train local operators to run the asphalt plant.

We are responsible for all the repairs that caused by our quality problems within one year’s warranty, and our equipments enjoy our after-sales service for life though they pass its warranty date.

Please click to view our detailed service system, all we want to do is to guarantee your buying our asphalt plants without any worry.

We will try our best to satisfy all of your special requirements for customizing asphalt plants. No matter you need hydraulic elevator platform, hot recycling device, or you need to reform your old asphalt plants, we will immediately react to your demands.