Highlights Of Eco-friendly Asphalt Plants

Environment-friendly asphalt mix plant is expected to replace traditional ones and become the mainstream of the market for its superiority in terms of saving resources and energy, reducing air pollution and noise pollution. The reason is that environmental problem has become a major global issue.governments of both the developed countries and the developing countries nowadays are paying more and more attention to environmental protection.

As a council member of Road Building Machinery Branch of China Construction Machinery Industry Association and a leader of road construction machinery manufacturers, LYROAD Machinery is willing to set an example and insists on researching and developing a number of technical patents, creating JNW, JJW and ELB series of asphalt mixing plants, which are highly praised by domestic and foreign customers for environmental-friendly designs, even those who come from developed countries where environmental protection demands are extremely harsh, such as the UK and Australia.

What are the environmental protection designs of JJW and JNW high-end series asphalt mixing plants?

Environmental protection designs of cold aggregate supply system

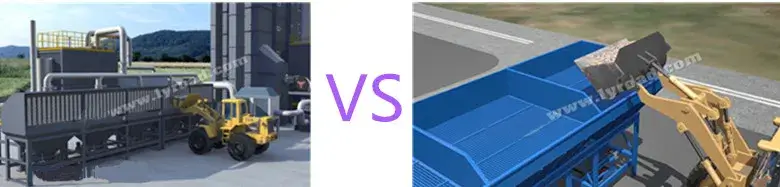

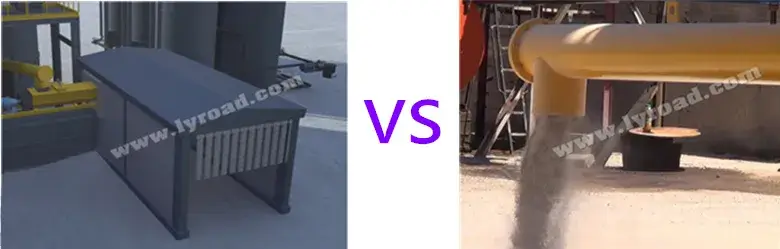

About the cold aggregate feeder

>Compare

Cold aggregate feeder of the traditional asphalt mixing plant is open upwards and not equipped with dust removal device, which causes the dust to float out when the cold aggregate is poured into cold aggregate feeder and the dust cannot be dispersed in a short time.The cold aggregate supply system used in JJW and JNW series asphalt mixing plants can make dust not appear out.

>Environmental protection designs

- Close upward opening and skillfully change the downward dumping type to the side window feeding type

- A pipe is installed on each hopper to form a negative pressure environment, the dust can be sucked into the baghouse dust collector through it

- The special "curtain" of window can greatly reduce dust spillage

About Belt conveyor

>Compare

The belt conveyor of the traditional asphalt mixing plant is not enclosed, and the cold aggregate is tilted nakedly to the drying drum after passing through the vibrating screen. During this process, dust constantly flows into the air. JJW and JNW series asphalt plants adopt enclosed belt conveyors, and no cold aggregate and dust are seen in the whole process.

>Environmental protection designs

- With the belt conveyor being completely packaged,the dust produced during the conveying process is fully not visible

- The filter screen at middle of conveying route is also entirety packaged, a pipe is installed on the top of it to form a negative pressure environment, through which dust can be sucked into the baghouse dust collector

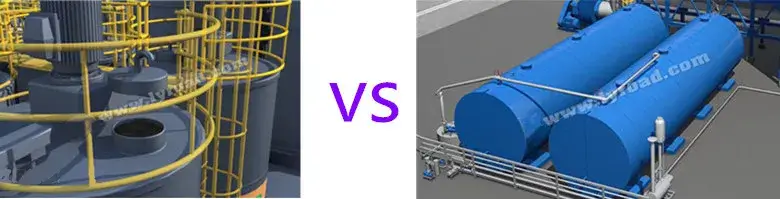

Environmental protection designs of bitumen supply system

>Compare

The pungent odor emitted by the heated bitumen is toxic to the human body and seriously pollutes the air. The horizontal bitumen tank used in the conventional asphalt mixing plant has no filtering device, and the smoke of heated bitumen is allowed to be discharged outwards through the exhaust port. While JJW and JNW series asphalt plants adopt vertical asphalt tanks, which can effectively filter the smoke, greatly reducing human injury and environmental pollution.

>Environmental protection designs

- On the exhaust port of the bitumen tank is equipped with high-efficiency activated carbon to filter bitumen smoke

- Extra-thick insulation is designed to wrap around outer surface of bitumen tank and pipes to reduce heat loss

Environmental protection designs of mixing tower system

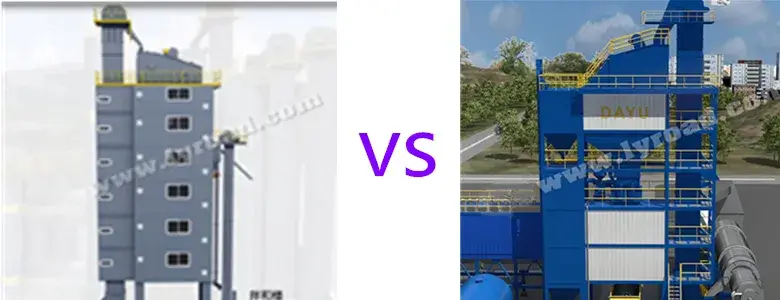

About The mixing tower

>Compare

The most important and bulky part of an asphalt mixing plant is the mixing tower.The mixing tower of traditional asphalt mixing plant is completely exposed,and the hot material elevator, weighing equipment and mixing equipment are clearly visible.There will be dust and loud noise outleakaging during the production process,causing air pollution and noise pollution.JJW, JNW series and ELB series asphalt mixing plants fully enclose mixing tower to solve these problems perfectly.

>Environmental protection designs

- Fully enclosed tower eliminates leakage of powder and surrounds all the dust inside

- Effectively isolate the sound from devices in the mixing tower to reduce noise pollution

- Equip the entrance and exit of the hoist with wear-resistant noise reduction device to reduce noise pollution

- Seal the whole vibrating screen tightly,and use device to ventilate it and release its pressure so as to save energy and protect environment

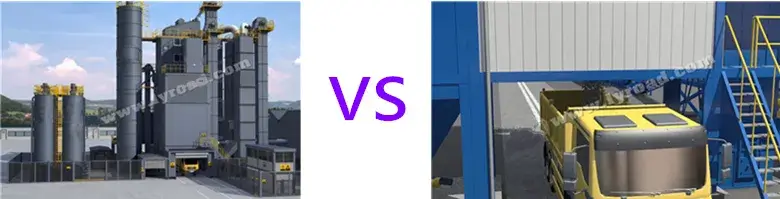

About the truck loading chamber

>Compare

Because there is no obstruction in the surrounding, the strong odor of the hot mixture quickly spreads to the surrounding,polluting the air and affecting people's physical and mental health.JJW and JNW series asphalt mixing plants adopt a fully enclosed loading chamber to effectively intercept the odor diffusion and reduce the noise volume.

>Environmental protection designs

- A pipeline is installed above the loading chamber and forms a negative pressure environment,bitumen smoke generated by the discharging process is transported to the drying drum through the pipeline to be heated and decomposedn

- The enclosed loading chamber is equipped with a dust removal pipe, and the dust enters the baghouse collector through the pipen

- Equip the exit of the loading chamber with an automatic lifting door, which is environmentally friendly and cleann

Environmental protection designs of powder recycling system

>Compare

The old powder generated is dumped from the outer discharge outlet of the dust collector in traditional asphalt mixing plant.When the wind is large, the dust is scattered everywhere, polluting the surrounding environment. JJW and JNW series asphalt mixing plants skillfully employ centralized storage,humidify and agitate the old powder and discharge it into the semi-closed dust collection room.

>Environmental protection designs

- After humidified and stirred, the old powder changes into mud or semi-mud, which reduces pollution and is easy to clean

- Add dust removal pipe above the dust collection room to form a negative pressure environment. The powder that has not been fully humidified and stirred enters the baghouse dust collector through the pipeline

- The old powder can be completely recycled and reused after being humidified, which is conducive to environmental protection

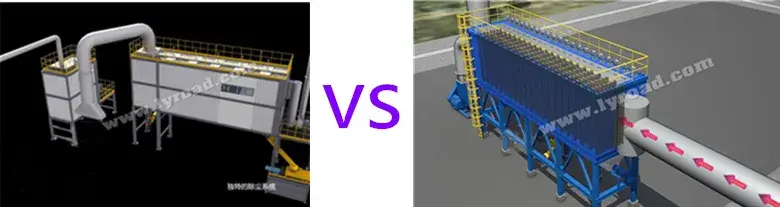

Environmental protection designs of dust collecting system

>Compare

Traditional asphalt mixing plants, such as the LB series mixing plants, are usually equipped with a volute dust collector and a baghouse dust collector to meet basic environmental requirements. JJW and JNW series asphalt mixing plants have higher environmental protection pursuits.In addition to conventional equipment, dust collecting system is equipped with two more baghouse dust collectors,which makes the dust removal system unique and have a better environmental protection effect.

>Environmental protection designs

- Add 2 additional baghouse dust collectors, one of which collects the dust generated when the cold aggregate is poured into the grading machine

- The other one is used to collect dust in the mixing tower specially

Environmental protection designs of central control system

>Compare

Due to the incomplete matching between the hot aggregate stock and the cold aggregate, the traditional asphalt mixing plant cannot avoid the hot aggregate overflow problem and cause waste of resources.JJW and JNW series asphalt mixing plants adopt intelligent automatic control to completely eliminate energy waste and environmental pollution.

>Environmental protection designs

- The automatic control system grasps the amount of material in each hot silo in real time through the self-weighting sensor, and automatically matches it with the cold aggregate, ensuring that the storage capacity in the hot filler bin is close to zero at the end of production

- It can avoid a large amount of dust caused by the discharge of the remaining hot aggregate at the end of production

Environmental protection designs of production operation process

>Compare

The traditional asphalt mixing plants cannot eliminate the extra hot aggregate,and the production materials are not fully utilized, resulting in waste of resources, which obviously causes environmental damage.By using the patented technology,JJW and JNW series asphalt mixing plants have many highlights,such as high measurement accuracy, high intelligence, low production and operation cost, high efficiency, large output, etc,which has an significant effects of energy saving and environmental protection.

>Environmental protection designs

- Aggregate measurement adopts small door, small flow and decrement measurement technology.Bitumen supply tracks the “oil-stone ratio” all the time, and adopts the reduction measurement method,these all greatly improve the dynamic measurement accuracy

- Use patented technology to solve the shortcomings of the traditional hot aggregate superposition weighing time, shorten the batch cycle, and greatly increase the output

- Use noise reduction, sound insulation, shock absorption and other measures to significantly reduce noise emissions in places where noise is generated from equipment

- JJW series adopt vertical drying tower, which has good sealing performance, less air leakage point, lower heating energy consumption, and more energy saving and environmental protection

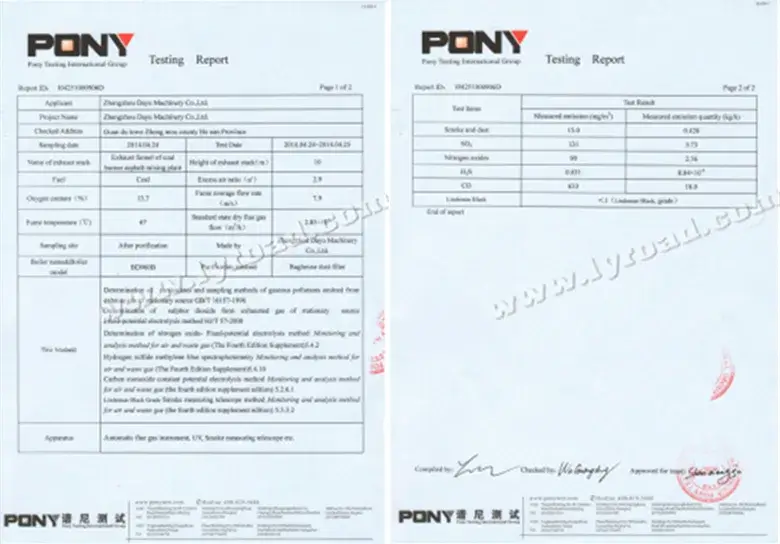

JJW, JNW series asphalt mixing plants meet international environmental standards

About air pollutant emissions

In 2014, LYROAD Machinery commissioned PONY Testing Group, a well-known third-party large-scale comprehensive testing organization in China to conduct environmental monitoring on all aspects of its products.PONY Testing Group finally issued an environmental impact test report with international credibility.

The report shows that the smoke and dust emission of the products of LYROAD Machinery is 15.0ug/m3, which is lower than the international standard of 20ug/m3.

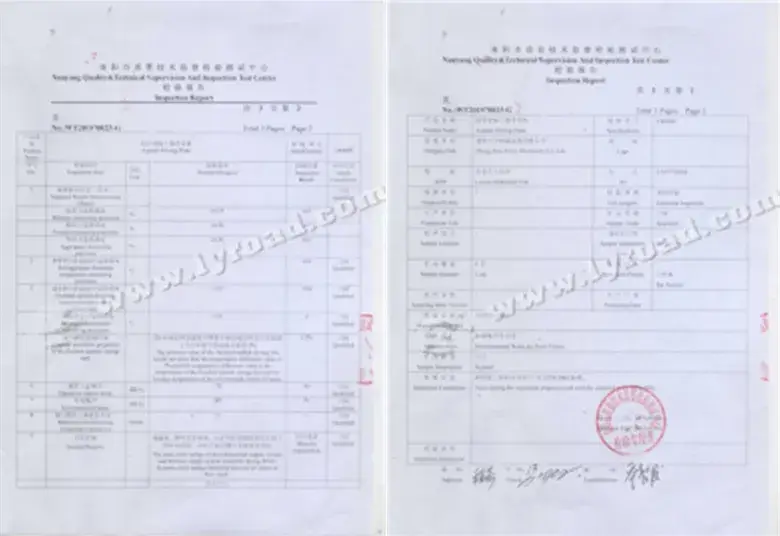

About noise emission

Nanyang Quality and Technical Supervision, Inspection and Testing Center was commissioned by LYROAD Machinery in 2015 to make noise detection on asphalt mixing equipment and issued a test report.

The report shows that the noise detection result of the operation station is 50dB, and the environmental noise detection result is 70dB, which is less than the upper limit of the national standard of 70dB and 85dB.