Environmental Asphalt Plant ELB Series

- Model: ELB700 ~ ELB5000

- Product Capacity: 60 t/h ~ 400 t/h

- Mixer Capacity: 700 kg/batch ~ 5000 kg/batch

- Highlights:

Stationary, batch mix, precise screening,accurate weighing;

Environmental-friendly, enclosed mixing tower, clean and safe.

Brief Introduction

Environmental-friendly Asphalt Plant is developed on the basis of LB Series; it retains the advantages of LB Series and attaches great importance on environmental protection and safety. ELB Series asphalt mixing plant is featured by low noise and less pollutant emission, fit for road construction projects in all grades and scales and can be set in urban or near urban area.

Product Parameters

| Model | Capacity (standard condition) |

Mixer Size | Fuel Consumption | Measurement Accuracy | |

| Oil | Gas | ||||

| ELB700 | 60t/h | 700kg | 5.5~7kg/t | 8~10m³/t | Aggregate:

±0.5% Filler: ±0.25% Bitumen: ±0.25% |

| ELB1000 | 80t/h | 1000kg | 5.5~7kg/t | 8~10m³/t | |

| ELB1200 | 100t/h | 1200kg | 5.5~7kg/t | 8~10m³/t | |

| ELB1500 | 120t/h | 1500kg | 5.5~7kg/t | 8~10m³/t | |

| ELB2000 | 160t/h | 2000kg | 5.5~7kg/t | 8~10m³/t | |

| ELB2500 | 200t/h | 2500kg | 5.5~7kg/t | 8~10m³/t | |

| ELB3000 | 240t/h | 3000kg | 5.5~7kg/t | 8~10m³/t | |

| ELB4000 | 300t/h | 4000kg | 5.5~7kg/t | 8~10m³/t | |

| ELB5000 | 400t/h | 5000kg | 5.5~7kg/t | 8~10m³/t | |

Main Features

1.High quality finished asphalt

①. 4 or 5-tier vibrating screen, hot aggregate are separately stored in different hot aggregate storage according to particle size;

②. METTLER TOLEDO load cells, ensuring accurate weighing of hot aggregate, bitumen and filler;

③. Batch mixing.

2. Optional feed for additives

①. Dye pigment;

②. Fibre;

③. Foam.

3. New structure design; enclosed mixing tower

①. Enclosed mixing tower with satey door, minimal dust and noise emission; unauthorized person are kept away from mixing tower, ensuring personal safety and equipment security;

②. Aggregate feeder and belt conveyor can also be enclosed (optional);

③.The plant can be set in urban area.

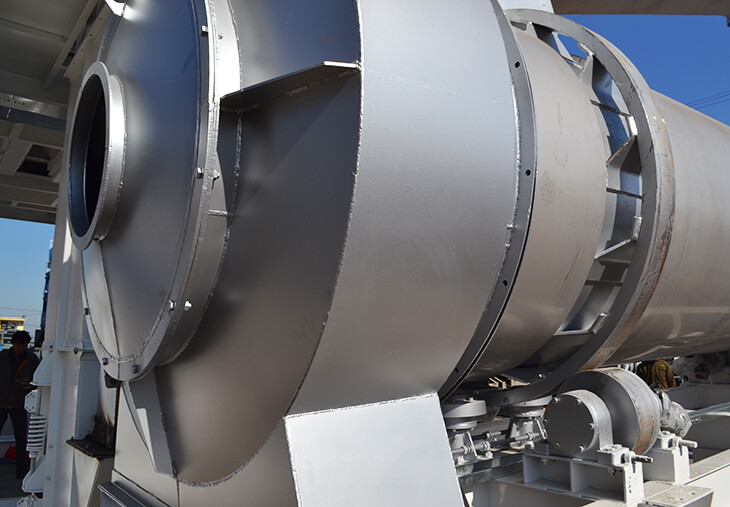

4. Optimized drying drum

①. Optimized inner structure, aggregate are fast and thorougly heated;

②. Drying drum is covered by thermal insulation layer, less heat loss;

③. Quality burner (diesel or gas), high combustion efficiency, less pollution;

④. Longer service life.

5. Two dust filtration system, less dust emission

①. First stage: cyclone dust filter;

②. Second stage: bag house filter;

③. Dust emission is less than 20mg/Nm3.

6. Safety devices

①. Guardrails are installed where aerial work is possible;

②. Security door is installed on the access to mixing tower, unauthorized person is kept out;

③. All catwalk and climb ladders are antislip.

Detailed Information