What Is Mobile Concrete Batching Plant

Mobile concrete batching plant is a kind of portable concrete production equipment that precisely proportions and mixes water, aggregates (such as rocks, gravel, and sand), cement, and fly ash to produce tens to hundreds of cubic meters of concrete per hour. Mobile batching plants are typically divided into two types: self-propelled and trailer-mounted. During operation, the coordination of equipment. such as concrete pumps and transit trucks is essential to ensure timely delivery and placement of the mixed concrete.

CONTENTS

- 1. Composition of a Mobile Concrete Plant

- 2. How Does A Portable Concrete Plant Work?

- 3. Mobile Concrete Plant VS Stationary Concrete Plant

- 4. Benefits of Mobile Concrete Batching Plants

- 5. Applicable Scenarios of Mobile Concrete Plants

- 6. Matters To Consider When Choosing The Right Portable Batching Plant

- 7. Where To Buy Mobile Concrete Batching Plants

- 8. Summary

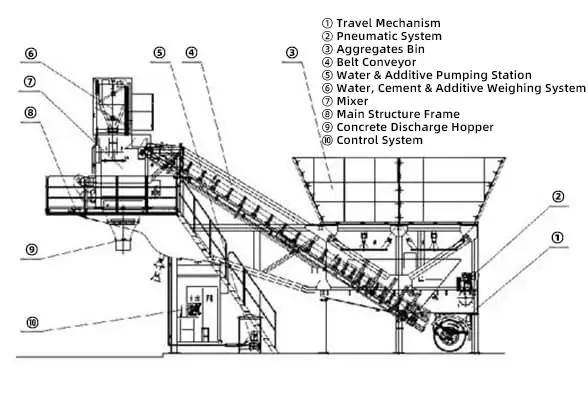

Composition of a Mobile Concrete Plant

The portable batching plant boasts a compact and multifunctional design, with its key components encompassing the following:

- Mixer: It serves as the fundamental component of the plant, responsible for mixing aggregates, cement, water and additives in a preset proportion to make concrete.

- Aggregate Feed System: It ensures accurate concrete mix proportioning by means of well-designed components such as aggregate bins, conveyor belts, and metering devices.

- Cement Storage System: Consisting of cement silo, screw conveyor and dust collector, it not only ensures sufficient cement storage, but also keeps cement dry and clean by leveraging advanced technical means, thereby capable of supplying high-quality raw materials for concrete production.

- Water and Additives Feed System: Employing a water tank, water pump, additive tank, and metering unit, the system precisely dispenses water and various additives to optimize concrete performance.

- Control System: Serving as the "intelligent brain" of the entire plant, it leverages electrical components, sensors, PLCs, and human-machine interfaces to achieve automated and intelligent management of the production process.

How Does A Portable Concrete Plant Work?

Briefly, measure materials such as aggregates, cement, water and additives, mix them in an accurate proportion to produce high-quality concrete, and then transport the final mixture to the construction site by means of the conveying system.

Step1: Feed Aggregates

Transport aggregates such as sand, crushed stone via a conveyor belt or hopper to a precision metering device, where they are accurately measured based on a preset proportion before being directed to the mixer.

Step 2: Add Filler

Deliver filler such as cement or fly ash to the filler metering unit by screw conveyor or pneumatic conveying system, and then add it to the mixer after accurate metering.

Step 3: Feed Water and Additives

The water/additive feed system delivers water and additives (such as water reducers and retarders) as appropriate to the mixer, in accordance with the performance requirements of the concrete.

Step 4: Mix

Upon activation of the mixing system, the rotation of the mixing blades thoroughly mixes aggregates, cement, water, and additives to form homogeneous concrete.

Step 5: Transport and Pour

After mixing is completed, finished concrete will be sent to the pouring site for construction by a delivery pump or mixer trucks.

Step 6: Clean and Maintain

After each production, clean and maintain the portable batching plant to ensure it remains clean and in optimal condition, thereby priming it for subsequent production.

Mobile Concrete Plant VS Stationary Concrete Plant

| Feature | Mobile Concrete Plant | Stationary Concrete Plant |

|---|---|---|

| Flexibility | High degree of flexibility, rapid transfer and installation , and remarkable adaptability | Low degree of flexibility, and relatively fixed position |

| Equipment Structure | Compact, integrated and easy to transfer | Large size, multiple equipment combination and fixed foundation required |

| Production Capacity | Customized to meet the needs of different scales | Suitable for large-scale and continuous production |

| Installation and Disassembly | Simple and quick, saving both time and efforts | Relatively complicated, time-consuming and labor-intensive |

| Applicable Scenarios | Small to medium-sized projects in remote and temporary locations | Large-scale, long-term and centralized production scenarios |

| Investment Cost | Low, suitable for small and medium investors | High, suitable for large or long-term operators |

Benefits of Mobile Concrete Batching Plants

1. High Flexibility

They can swiftly adjust to diverse and dynamic engineering environments, and are capable of rapid relocation and installation in confined urban settings or remote regions, thereby ensuring seamless project advancement.

2. Automation and Intelligence

The integration of various concrete production processes enhances production efficiency, lowers costs, and guarantees consistent concrete quality through precise measurement and control, leading to increasingly intelligent and automated concrete production processes.

3. Easy installation and Disassembly

Greatly shortens the preparation and closing time of the project, offering substantial advantages for projects with strict deadline requirements.

4. Outstanding Environmental Performance

By employing enclosed design, the emission of dust and noise is effectively reduced, while the optional wastewater recycling system enables resource recycling, which realizes remarkable results in reducing environmental impact.

Get Pricing Info for Mobile Concrete Plants

Applicable Scenarios of Mobile Concrete Plants

1. Municipal Works

For projects characterized by fluctuating construction sites and stringent timeline, movable concrete mixing plants ensure the seamless development of critical infrastructure like roads and bridges.

2. Civil Works

Portable concrete batch plants furnish a consistent concrete supply for expansive commercial ventures and residential zones to fulfill construction requirements.

3. Water Conservancy and Hydropower Works

Mobile concrete batching plant demonstrates exceptional performance in remote mountainous regions or river regulation, underscoring their benefits of mobility and autonomy.

4. Disaster Rescue and Relief

Rapid deployment delivers concrete in urgent need to disaster areas for the construction of temporary facilities.

5. Environmental Protection Works

Equipped with low-emission and wastewater recovery system, mobile concrete plants provide environmental protection concrete scheme for ecological restoration.

6. Medical Works

While the utilization of portable concrete batching plants in the medical sector remains uncommon, mobile concrete batching plant expedites the production of concrete foundations and isolation facilities in temporary field hospitals or emergency rescue centers, thereby offering essential support for medical rescue operations.

Ready to Mobilize Your Concrete Production? Inquire Now!

Matters To Consider When Choosing The Right Portable Batching Plant

When choosing a portable concrete batch plant, the following key aspects should be considered comprehensively:

1. Scale and Demand

In order to satisfy the concrete volume and production speed mandated by the project, comprehensive comparison and selection should be made on the basis of determining the capacity and type to guarantee alignment with project requirements and optimize production efficiency.

2. Mobility

The possible relocation of the project site and the frequent need to transfer equipment necessitate careful consideration of mobility. To expedite the execution of engineering tasks and enhance operational efficiency, a self-propelled or trailer-mounted mobile concrete plant with excellent mobility should be chosen for swift and convenient equipment transfer between locations.

3. Equipment Quality

Equipment selection should prioritize brand reputation, quality, and comprehensive after-sales support. The selection of high-performance and proven mobile concrete plants and associated equipment can significantly reduce failure rates and minimize related maintenance costs, while ensuring the project's smooth implementation.

4. Safety Factor

To guarantee the safety of operators and the uninterrupted functionality of the equipment, it is imperative to ensure that the equipment complies with pertinent safety standards and is equipped with comprehensive safety protection mechanisms. In addition to the performance of emission control, noise control and dust control of equipment, safety factors including environmental protection should also be duly taken into consideration.

5. After-sales Service

To ensure prompt and efficient assistance in the event of equipment malfunction, it is necessary to evaluate the supplier's after-sales service policy and quality, encompassing the duration of equipment warranty, responsiveness of maintenance services, and availability of spare parts.

6. Economic Benefits

On the premise of meeting the engineering requirements, portable batching plant with the highest cost performance should be selected on the basis of comprehensive consideration of equipment purchase cost, operation cost, maintenance cost and long-term return on investment, so as to maximize economic benefits.

Explore Portable Batching Plant Options and Request Pricing!

Where To Buy Mobile Concrete Batching Plants

Currently, ACE stands as a premier global manufacturer of mobile concrete plants, renowned for their exceptional performance, quality, and exemplary after-sales support, solidifying its position as an industry front runner.

- Product Introduction: In the realm of specialized expertise, ACE is dedicated to the research, development, and production of a diverse range of mobile concrete batching plants. These plants are categorized into self-propelled and trailer-mounted variants, tailored to meet the requirements of various scales and types of construction projects.

- Product Performance: The mobile concrete plant, boasting efficient and stable production capacity, developed by ACE, has garnered widespread recognition and acclaim within the industry. Its advanced mixer, accurate metering system and intelligent control system ensure the stability of concrete quality, providing reliable guarantee for continuous production. In addition, ACE has demonstrated a strong commitment to integrating environmental conservation and energy-efficient technologies into their operations, delivering eco-friendly and sustainable concrete production processes and solutions to their customers.

- After-sales Team: ACE has won the trust of customers with its perfect after-sales service system. The company has established a professional technical support team, which provides customers with timely and comprehensive technical support and solutions.

Summary

With the continuous advancement of technology and the increasing complexity of engineering construction, mobile concrete plants are poised for a broader scope of development in the future, moving towards a higher level of automation, intelligence, and environmental friendliness. The leverage of cutting-edge control system sensor technology and innovative materials will significantly enhance equipment production efficiency, safety, and environmental, paving the way for substantial growth opportunities in associated industries. As the global infrastructure development progresses steadily, the market demand for mobile concrete stations will continue to experience continuous growth.