Asphalt Plant China

In the market for a new asphalt plant and want to score a killer deal straight from China? This article is your one-stop shop for everything you need to know. We'll dive deep into the Chinese asphalt plant industry, showing you why their products are built to last, easy on the wallet, and come with top-notch service. Plus, we'll give you some pro tips on buying asphalt mixing equipment directly from China.

CONTENTS

- 1. Asphalt Plants In China

- 2. The Advantages of China Asphalt Plants For Sale

- 3. The Best China Asphalt Plant Manufacturer

- 4. Why Does China Asphalt Mixing Plant Price Have an Advantage?

- 5. Tips For Buying Chinese Asphalt Mixing Plants

- 6. Choose The Best Asphalt Plant Manufacturer in China as Your Partner

Asphalt Plants In China

China stands as the world's largest producer of asphalt, possessing a production capacity of up to 71 million t/a and a market exceeding CNY 200 billion in 2022, and now it also stands as the largest asphalt plant manufacturing country.

Brands Co-existing On China Market

In the realm of asphalt production plant, multinational corporations such as Marini and Ammann established a foothold in the Chinese market at an earlier stage and dominate the high-end market. Through years of dedicated development and accumulation, local asphalt plant brands represented by ACE has steadily refined their product portfolios and enhanced their technical service offerings. Consequently, local products have progressively captured a significant share of the domestic high-end equipment market.

Types and Application Scenarios of Asphalt Plants

The diverse demands for asphalt in the Chinese market are driving asphalt mixing plant manufacturers to innovate new types of plants, expand new markets, and cater to emerging needs. China boasts a diverse array of asphalt plant types, characterized by a broad spectrum of production capacities. Briefed as follows:

| Key Criteria | Categories |

|---|---|

| Transport Mode | Mobile, semi stationary, and stationary |

| Production Capacity | Small (less than 40 t/h); Medium(40 t/h to 400 t/h); Large(over 400 t/h) |

| Mixing Mode | Forced batch, continuous drum |

In an asphalt batching plant, aggregates, filler, bitumen and other additives are sequentially introduced in measured quantities, vigorously mixed for a preset period (typically around 45 seconds), and then discharged and circulated. In contrast to batch mix plants, which ensure precise measurement and homogenous mixing for high-quality product, drum type plants continuously feed and blend materials within a rotating drum, making them suitable for projects that require high production output but have relatively less strict accuracy requirements for the mixture.

Furthermore, by functional characteristics, some paving material equipment that are specifically tailored to produce colored asphalt concrete cater to the unique requirements of scenic roads and other specialized projects, while some RAP asphalt plants have the capability to recycle waste asphalt pavement materials.

Innovation of Asphalt Batching Plant China

The Chinese HMA plant manufacturing industry is at the forefront of innovation in several key areas as follows:

1. Novel Technological Applications

Research and development efforts have yielded equipment capable of producing modified asphalt with enhanced temperature and ultraviolet resistance, catering to the demands of extreme environments.

2. Digitalization and Intelligent Management

The strategic integration of big data and cloud computation facilitates real-time monitoring and optimization of production, sales, and logistics throughout the entire value chain.

3. Green Manufacturing and Economical Recycling

The whole industry nowadays prioritizes sustainable development by embracing clean production technologies and resource recycling practices, thereby minimizing environmental impact and resource depletion.

The Advantages of China Asphalt Plants For Sale

Among the prominent advantages of Chinese batching asphalt plants are:

1. Low Manufacturing Cost

China's well-developed supply chain and production system translates to significant cost control advantages. Such advantage can be passed on to customers in the form of lower prices, making Chinese-made asphalt mixing plants more competitive in the international market.

2. Energy Conservation and Environmental Protection

As the concepts of "Carbon Peaking" and "Carbon Neutrality" are becoming increasingly prevalent, tighter environmental regulations are pushing demand for eco-friendly equipment. Consequently, Chinese bitumen plant manufacturers are placing a strong emphasis on energy efficiency and resource optimization in their designs, driving ongoing improvements in environmental performance.

3. Product Line Diversification

Chinese hot mix asphalt plant manufacturers cater to a wide range of project needs, offering customization options for both compact mobile and expansive stationary plants. Such remarkable flexibility and diversity are hallmarks of China's asphalt production equipment industry.

4. Technological Progress and Innovation

Fueled by China's ever-evolving manufacturing sector, asphalt batching plant manufacturers are demonstrably enhancing their capacity for technological innovation, which manifests in the ongoing integration of novel technologies, materials, and processes during design and production, ultimately elevating the technical sophistication and additional value of their products.

5. Market Adaptability

Chinese asphalt mixing plant manufacturers have the ability to promptly adjust their product strategies, swiftly respond to market fluctuations, and effectively address diverse market demands across various regions and developmental phases. This keen market sensitivity and adaptability stand as significant advantages for Chinese enterprises in the global market competition.

While China's road paving materials plant is steadily improving overall, a gap remains in the high-end market regarding brand recognition and cutting-edge R&D compared to established international players. In addition, as Chinese enterprises venture into the international market, they encounter a plethora of challenges related to certification requirements and technical standards. Meeting the EU CE certification or complying with region-specific safety and quality standards poses significant hurdles for their entry into global markets.

The Best China Asphalt Plant Manufacturer

LYROAD, a subsidiary of ACE Group, is a renowned asphalt plant manufacturer in China. Since 2004, LYROAD has been dedicated to the research, development, manufacturing, and sales of asphalt mixing plants, concrete mixing plants, and other related road construction machinery.

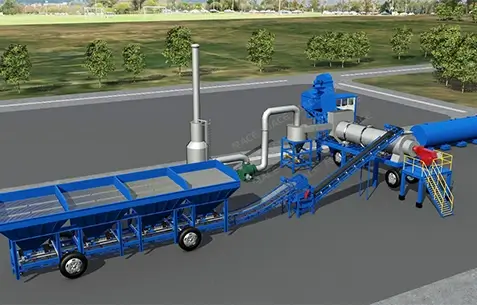

The asphalt mixing plant product line of ACE Group offers a diverse range of asphalt mixing plants, including batch mix and drum mix plants. They are classified based on mobility as stationary, semi-stationary, and mobile asphalt plants. In terms of production capacity, they range from small/mini-scale to medium and large-scale plants, with capacities ranging from 40t/h to 400t/h, catering to various road construction requirements.

ACE Group has earned widespread trust from domestic and international customers due to its excellent product quality, comprehensive after-sales service, and a good market reputation. The key highlights of its asphalt plant products include:

- Technological Advancement: ACE Group integrates cutting-edge technology and innovative features into its asphalt equipment to ensure optimal performance, efficiency, and durability.

- Customization Options: ACE Group focuses on meeting customer needs by offering customization options to tailor asphalt equipment according to specific project requirements.

- Quality Assurance: ACE Group maintains strict quality control measures throughout the manufacturing process to deliver high-quality asphalt equipment that meets international standards.

- Comprehensive Support: From initial inquiries to after-sales support, ACE Group provides comprehensive assistance to customers, ensuring a seamless experience and maximum satisfaction.

Why Does China Asphalt Mixing Plant Price Have an Advantage?

Chinese asphalt batching plants boast a favorable cost performance, primarily attributable to the following aspects:

1. Budget-friendly Manufacturing

China's plentiful labor force, established industrial ecosystem, and advanced manufacturing technologies all combine to reduce production expenses, giving Chinese hot mix plants a competitive advantage in pricing.

2. Excellent Performance

Driven by continuous technological advancements and innovation, China-made AMPs exhibit efficient, stable, and reliable production capabilities, which translates to high levels of production efficiency, asphalt quality, and equipment service life.

3. Perfect Service

Leading Chinese hot mix asphalt plant manufacturers excel in providing comprehensive after-sales service, encompassing equipment installation, commissioning, maintenance, and technical support. Such comprehensive approach ensures customers receive timely and effective assistance throughout the equipment life cycle, ultimately enhancing their use experience.

| Plant Location | Egypt |

| Installation Date | 2021/11/02 |

| Model | LB1500 Asphalt Batch Mix Plant |

| Type | Batch Mix / Hot Mix |

| Capacity | 120TPH (Standard Working Condition) |

| Mixer Capacity | 1500kg/batch |

| Air Emissions | ≤20mg/Nm³ (baghouse dust collector) |

| Customer Feedback: Outstanding performance, high efficiency, and top-notch after-sales service. Investing in LYROAD's asphalt plant has proven to be a reliable, low-maintenance investment, greatly enhancing our construction projects. | |

Inquire Now for Competitive Pricing

Tips For Buying Chinese Asphalt Mixing Plants

International buyers are advised to focus on the following key considerations when procuring a Chinese asphalt batching plant.

1. Verify The Identity of Your Partner

Confirm if the supplier is the actual manufacturer to prevent cost escalation or elongation of the service chain as a result of intermediary procurement. Consider conducting an on-site visit to the factory, or alternatively, review past successful cases to assess the manufacturer's capabilities and reputation effectively.

2. Understand The Partnership and Market Reputation

Explore the collaborative dynamics between Chinese manufacturers and their international counterparts, including the presence of joint development initiatives, technology transfer arrangements, and brand licensing agreements. View user reviews and feedback on social media platforms to gain comprehensive insights into its performance and reliability within the global market.

3. Understand Product Quality and Standard Compliance

Thoroughly assess product compliance with international quality standards (e.g., ISO, CE, EAC) to guarantee alignment with industry regulations and construction specifications at the project site, ensuring optimal performance, safety, and durability of the equipment. Request the manufacturer to furnish comprehensive product specifications, test reports, and pertinent certification documentation.

4. Assess The Feasibility of Accommodating Customization Requirements

For projects with unique technical needs or stringent environmental regulations, it's crucial to verify if the manufacturer can customize the equipment to function effectively within your specific local conditions. It is imperative to take into account the universality of accessories and consumables, along with the ease of subsequent replacement for enhanced convenience.

5. Confirm The Availability of Transportation and Customs Declaration Services

Inquire about the supplier's experience in exporting large-scale equipment and their ability to provide comprehensive integrated services, encompassing packaging, transportation, and customs clearance at the destination port. Discuss and determine the risk-sharing mechanisms, insurance provisions, and supplementary expenses pertinent to transportation.

6. After-Sales Service and Technical Support

Validate the provision of worldwide after-sales support by the supplier, while assessing response time, spare parts availability, and maintenance strategies. Clearly define the after-sales service provisions, including the warranty period, repair costs, and technical personnel training.

Contact Us Now To Get Accurate Asphalt Plant Price

Choose The Best Asphalt Plant Manufacturer in China as Your Partner

As a leading preeminent China’s asphalt plant manufacturer, especially as an asphalt plant manufacturing expert, ACE Group has formed the significant ability to provide our customers with integrated solutions. By far, more than 500 sets of pavement material plants have shown their presence in more than 90 countries and regions.

20+ years of asphalt mixing plant manufacturing history, strong product lineup with more than 80 models available, along with 40+ core patented technologies, are what make ACE Group entitled to be one- of-the-kind asphalt plant manufacturer in China.