Mobile Concrete Batching Plants For Sale

Mobile concrete batching plant is a transportable and easy-to-assemble plant used to manufacture batches of concrete mix time-savingly and efficiently. With all units fixed on one or two chassis, it can be towed by a truck tractor, implement faster and easier installation, disassembling, and translocating. The entire plant is pre-wired and plumbed for air and water, requires less concrete foundation, and sometimes no permission. It is especially suitable for the construction of small and medium-sized hydropower, highways, ports, airports, bridges, etc.

Portable concrete batching plant price varies from $52,700 to $300,000. The production capacity normally has a span from 25m³/h and 100m³/h, compared with that of stationary concrete factory widely from 25m³/h to 150m³/h. Basically you can say, the procurement cost of a mobile batch plant is mainly up to the production capability. As customization becomes a clear trend, the configurations specified by users increasingly profoundly influence the purchase costs.

New Ones For Sale (8 Listings)

Transportable Batching Plant YHZS35

| Model: | YHZS35 |

|---|---|

| Capacity: | 35m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 47.05kW |

| Total Weight: | 19T |

Trailer Mobile Concrete Mixing Plant YHZS75

| Model: | YHZS75 |

|---|---|

| Capacity: | 75m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 88.75kW |

| Total Weight: | 32T |

Portable Ready Mix Batch Plant YHZS50

| Model: | YHZS50 |

|---|---|

| Capacity: | 50m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 61.75kW |

| Total Weight: | 20T |

Modular Mobile Precast Concrete Factory YHZS35

| Model: | YHZS35 |

|---|---|

| Capacity: | 35m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 47.05kW |

| Total Weight: | 19T |

Portable RMC Manufacturing Equipment YHZS75

| Model: | YHZS75 |

|---|---|

| Capacity: | 75m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 88.75kW |

| Total Weight: | 32T |

Small and Flexible Batching Plant YHZS25

| Model: | YHZS25 |

|---|---|

| Capacity: | 25m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 35.55kW |

| Total Weight: | 17T |

Movable Concrete Mixer Plant YHZS50

| Model: | YHZS50 |

|---|---|

| Capacity: | 50m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 61.75kW |

| Total Weight: | 20T |

Portable Precast RMC Production Mill YHZS35

| Model: | YHZS35 |

|---|---|

| Capacity: | 35m³/h |

| Discharging Height: | 3,800mm |

| Installed Power: | 47.05kW |

| Total Weight: | 19T |

Mobile Concrete Batching Plant Price list 2021

| Best Products | Price |

|---|---|

| YHZS25 | $100,000+ |

| YHZS35 | $120,000+ |

| YHZS50 | $200,,000+ |

| YHZS75 | $250,000+ |

Portable batching plants, first of all, are not more costly than the stationary ones. However, lower price is not the sole reason for users from a variety of countries to keen on buying them. Just like the transportable asphalt plants, there are a few of regions movable batching plants are most appliable to. Some certain projects needing served equipment to transfer from one place to another frequently are inclined to take portable RMC plants as the prior choices, as long as the production capacity can match with the scale of the projects. From our observations, portable batching plants have been sold well in India, South Africa, Kenya, Australia, UK, Philippines, Canada, USA, Ethiopia, Pakistan, Sri Lanka, Brazil, Bangalore, Nigeria, Malaysia, Myanmar, etc.

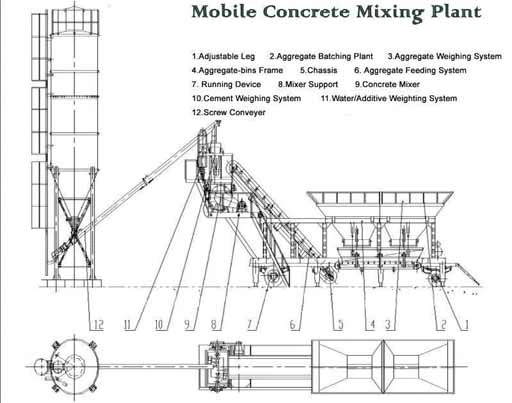

Mobile Concrete Batching Plant Structure

Main Components of Mobile Concrete Batching Plant

- Chassis with axles and wheels

- Control room

- Ingredients measurement system

- Belt conveyor frame

- Peripheral components

- Mixer

The mobile concrete mixing plant is a concrete production equipment that integrates the material storage, weighing, conveying, mixing, unloading and automatic control systems into a trailer unit.

At present, portable concrete plants are mainly divided into two types: traction type and trailer type. They usually uses a two-stage process and cumulative measurement method. Material silo is a big burden of the mobile plant, and so reducing the capacity of the silo is a necessary means to reduce the weight and volume of the equipment. But sometimes when the volume of the silo is reduced, the materials feeding may be interrupted. Therefore, a supplying device with good fluidity is required.

Detailed Instructions On The 6 Parts Of Batching Plant

1. Chassis

The chassis contains the towing pin and parking legs of the trailer truck; the metering scale of the mixer, cement and water admixture is placed on the chassis; the inspection walking platform, railings, etc. are attached to the periphery.

2. Control Room

The control room is at the bottom of the chassis, and is equipped with a fully automatic control system for the mixing plant. All its control circuits do not need to be disassembled.

3. Ingredient Measurement System

This system is located at the back end of the whole station. The upper part is an aggregate (sand, stone) storage hopper, and a heightening plate is set to increase the storage capacity. The door is opened pneumatically in sequence; the bottom is equipped with a walking rear axle and frame legs when working.

4. Belt Conveyor Frame

The frame is a truss structure connecting the chassis and the aggregate batching frame, and a belt frame is installed inside to integrate the main frame, the belt frame and the batching frame into a whole.

5. Peripheral Components

Peripheral parts such as cement silo and screw conveyor are integral parts during work or transportation, and can be transported and disassembled as a whole without disassembly.

6. Mixer

Generally, JS-type mixer is used, which can quickly and evenly mix to complete the fluidity and dry hard concrete.

Advantages of Mobile Concrete Plant

1. Rapid disassembly and assembly, convenient movement

During the transition, except for the screw conveyor and the cement hopper, the entire plant can be transported; other things such as the walking platform and the heightening plate are folded down, and all the control cables do not need to be disassembled. The removed accessories can be taken away with the plant. It only takes three days from installation to use.

2. Fast mixing speed, wide mixing scope and high mixing effects

Other properties, operation methods and principles are the same as the stationary batching plant (Please refer to How Does A Concrete Batching Plant Work).

3. “Click to supplement” technology

The patented technique can ensure the dynamic weighing accuracy of±1% is aways reached.

4. Containerized design, maritime cost cutted down

The overall dimensions of the transportation unit of all parts of the mobile plant are smaller than the container's internal empty size requirements, and three 40-foot containers are required for transportation of the entire equipment.