Asphalt Rubber Blending Plant

- Model: LXJ-10, LXJ-10L

- Agitator Motor Power: 15kW ~ 22kW

- Highlights:

Producing stable and reliable crumb rubber asphalt;

Containerized structure, ease of transportation.

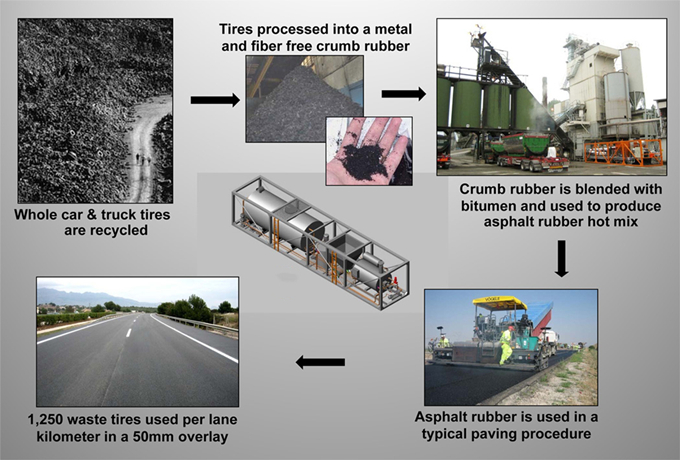

LYXL Series asphalt rubber blending plant is used to produce rubberized asphalt concrete (RAC). Rubberized asphalt is a special pavement material consisting of approximately 75-80 percent regular asphalt with 20 percent (+/-2%) crumb rubber made from scrap tires. Rubber asphalt overlays on road surface make road smoother, effectively reduce traffic noise and prolong road service time, having bright future and wide application in highway construction. Meanwhile, asphalt rubber blending equipment recycles a large number of scrap tyres, helping to save resources and reduce pollution.

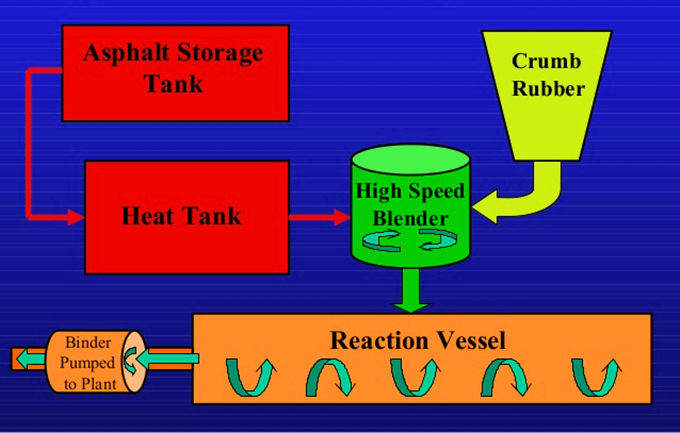

Crumb rubber made from scrap tires is loaded into the hopper before mixing begins and must be replenished during the mixing process. Next the screw conveyor carries the crumb rubber to the mixing chamber. Then, the crumb rubber is blended with virgin asphalt by a high shear mixer running at a speed of 3400 rpm. As the materials are mixed, they are pumped to the portable holding tank. During the mixing process, fresh materials are continuously fed into the chamber until the required volume of material has been mixed.

| Product Model | LXJ-10 |

|---|---|

| Heat Transfer Oil Boiler Capacity | 400,000kcal |

| Burner Model | RL-50 |

| Thermal Oil Circulating Pump Flow Rate | 40m³/h |

| Finished Tank Volume | 12m³ |

| Thermal Insulation | 10cm, Rock Wool |

| Agitator Motor Power | 22kW |

| Heat Transfer Oil Pipeline | DN50×200m |

| Screw Conveyor for Rubber Powder Feeding | 10t/h |

| Load-out Pump Capacity | 25m³/h |

| Product Model | LXJ-10L |

|---|---|

| Heat Exchange Area | 100m²×2 |

| Basis Bitumen Pump Flow Rate | 16m³/h, Variable Frequency Control |

| Rubber Powder Screw Conveyor Capacity | 5t/h |

| Rubber Powder Scale | Variable Feeding Rate |

| Rubber Powder Metering Hopper | 3m³ |

| Mixing Tank Capacity | 1m³ |

| Agitator Power | 11kW |

| Thermal Insulation | 10cm, Rock Wool |

| Rubberized Asphalt Pump Flow Rate | 18m³/h, Variable Frequency Control |

| Preparation Tank Volume | 20m³ |

| Agitator Motor Power | 15kW |

| Heat Transfer Oil Pipeline | DN50×100m |

1. Compact frame structure, ease of transportation; intelligent control, convenient for operation, ensuring stable and reliable performance.

2. Advanced process technology, adopt American McDonald Technology.

3. Powerful heat transfer oil heater and large area heat ex-changer, reaction kettle is heated rapidly, ensuring the quality of finished rubber asphalt.

4. High performance homogenizing devices in tanks prevent material from segregation, precipitation and swelling.

5. Accuracy of the weighing system is less than 2%, proportion of crumb rubber powder is adjustable.

6. Production volume of each cycle can be set freely within the maximum productivity.

7. Tanks are made by anti-corrosion stainless steel with good heat insulation device, static insulation index is ≤12℃/8h.

8. Stainless steel plates are adopted for packaging for corrosion resistance.

Your inquiry will be replied within 24 hours.