Pulverized Coal Burner

- Model: RM500 ~ RM4000 pulverized coal burner

- Power: 31.25 kw ~ 202.45 kw

- Matching Asphalt Plant Output: 25-40 t/h ~ 280-320 t/h

Introduction

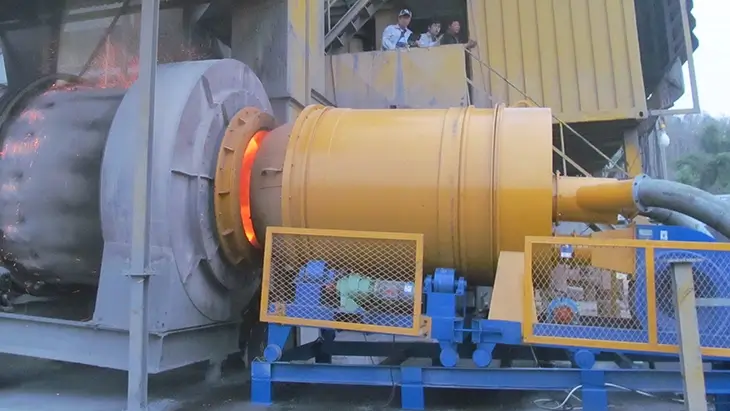

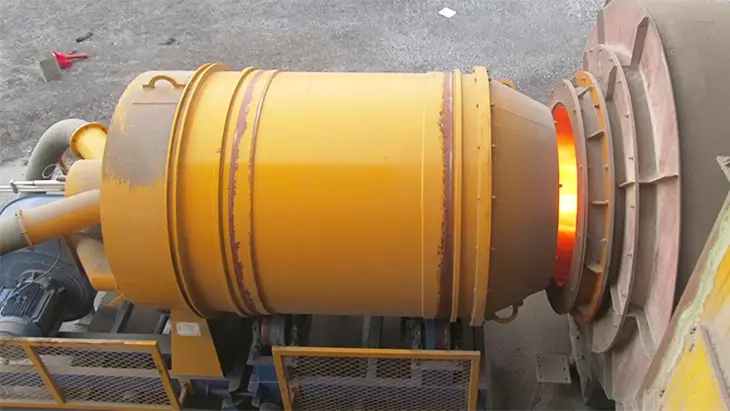

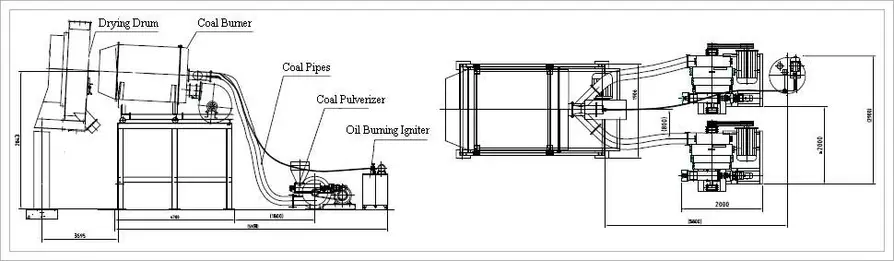

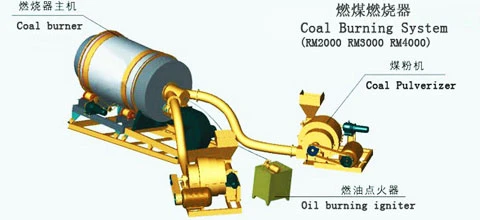

RM series pulverized coal burner is a new type coal combustion burner supported by FMJ series coal pulverizer. Coal Burner mainly consists of coal burner, coal pulverizer and igniter. Pulverized Coal Burner has many outstanding characteristics such as smoke abatement, energy conservation, environment protection, working conditions improvement, reduced labor intensity, etc. Pulverized Coal Burner is an ideal heating equipment.

Environment friendly: combustion completeness ≥95%, air black: Ringelmann 0-I grade, no harm to environment.

Technical Parameters

| Model | RM500 | RM1000 | RM1500 | RM2000 | RM3000 | RM4000 |

| Power | 31.25 kW | 41.25 kW | 73.75 kW | 80.25KW | 138.45 kW | 202.45kW |

| Rated coal consumption | 500 kg/h | 1000 kg/h | 1500 kg/h | 2000 kg/h | 3000 kg/h | 4000 kg/h |

| Mixture temperature control | 130-180℃ | 130-180℃ | 130-180℃ | 130-180℃ | 130-180℃ | 130-180℃ |

| Main machine | LTZ40 | LTZ80 | LTZ120 | LTZ160 | LTZ240 | LTZ320 |

| Coal pulverizer | FMJ40 | FMJ80 | FMJ120 | 2*FMJ80 | 2*FMJ120 | 3*FMJ120 |

| Oil burning igniter | RYDH | RYDH | RYDH | RYDH | RYDH | RYDH |

| Distribution cabinet | PD40 | PD80 | PD120 | PD160 | PD240 | PD320 |

| Combustion completeness | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Matching asphalt plant output | 25-40 t/h | 70-85 t/h | 100-125 t/h | 140-170 t/h | 200-250 t/h | 280-320 t/h |

Notes: FMJ series coal pulverizer, used for producing and supplying coal powder for coal burner. powder particle size: 200mesh.

Main Structure

Main Features

1. Coal powder stays in the hot zone of pulverized coal burner for long time, it kinds increases the combustion efficiency. Vaporous white smoke directly gets out of the chimney instead of black smoke.

2. The heating process is shortened, rising the thermal efficiency, and low requirements on coal quality, brings high economic efficiency.

3. Easy ignition greatly increases the working efficiency.

4. The air and coal volume can be changed on demand, besides, the burner temperature and flame shape can be adjusted in a wide range to meet the actual need.

5. The temperature field is even and large, the slag won’t stick on the surface, and the heating effect is powerful.

6. Application of exclusive high-performance heat resistance bricks to extend the serivce life.

7. Newest coal pulverizer with special made coal hammer that can produce coal particle ≥200 mesh.

8. Automatic pulverized coal adding devices, frequency control system, remote control.

9. Reasonable structure, excellent overall performance: good looking appearance, complete supporting facilities, tiny resistance and easy maintenance.

Requirements of Fuel

1. Use 0 # diesel for oil burning igniter.

2. Requirements for coal used for burning:

(1) Mark of coal: bituminous coal;

(2) Gross calorific value:≥5000kcal/kg (≥ 20000kJ/kg); Net calorific value:≥4200kcal/kg;

(3) Volatile matter:≥25%;

(4) Ash Content: ≤10%;

(5) Total moisture: ≤35%;

(6) Inherent moisture:≤14%;

(7) Total sulphur:≤1%;

(8) Particle size:≤20mm.

(9) Environment friendly: combustion completeness ≥95%, air black: Ringelmann 0-I grade, no harm to environment.

Note: These indexes are the lowest requirements for the coal, the better coal will be better at practice.

The Cost Comparation of Oil Burner and Coal Burner of Asphalt Mixing Plant (Calculated as per LB2000 (160t/h) with 10 hours working per day)

| Cost | Fuel Oile | Fuel Coal |

| 1 Ton of Asphalt Mixture | 7L | 12L |

| Price | 4 RMB/L | 4 RMB/kg |

| 1600T/day Daily Cost | 44800 RMB | 13440 RMB |

| Electric Charges | 30Kw × 10 hours × 1 RMB = 300 RMB | 118Kw × 10 hours × 1 RMB = 118 RMB |

| Labor Cost | None | 4 people × 40 RMB = 140 RMB |

| Total Daily Cost | 45100 RMB | 14780 RMB |

| Note: this price is based on China standards | ||

Components

Shippments