What Is Asphalt Recycling Plant?

An asphalt recycling plant, also known as asphalt recycling equipment, is a specialized factory device used for processing recycled asphalt pavement materials—RAP (Hereinafter referred to as RAP).

CONTENTS

Environmental protection has been a hot topic in all walks of life around the world in recent years, and environmentally friendly products have also received strong support from various countries and are favored by many companies. Asphalt recycling plant is a kind of equipment that specializes in recycling asphalt pavement materials, which is widely used for road construction.

What is Reclaimed Asphalt Pavement (RAP)?

RAP is the core material of asphalt recycling equipment, which is mainly obtained from old asphalt pavement through milling, crushing, and other processing techniques.

Properties of Reclaimed Asphalt Pavement (RAP)

To ensure the performance of recycled asphalt mixtures:

1. Cleanliness

RAP must be kept dry and clean, and should not contain impurities such as base layer waste, debris, soil, etc.

2. Particle size

The max. particle size of RAP should be less than the max. nominal particle size of the recycled asphalt mixture.

3. Asphalt content

The asphalt content in RAP is an important indicator, as both excessively high and low asphalt content can affect the performance of recycled asphalt mixtures.

4. Storage

To prevent clumping and asphalt aging, RAP should be stacked on a flat, solid, and hard surface, and long-term stacking should be avoided.

5. Pre-processing

Before use, RAP should undergo preprocessing steps such as crushing and screening to remove impurities and adjust the particle size distribution to meet the requirements of the recycled asphalt mixture. (Refer to the table below for specific details.)

| Material | Project | Technical Requirements | Methodology |

|---|---|---|---|

| RAP | Moisture content /% | ≤3 | T0305 |

| RAP grading | Actual measurement | T0327 | |

| Asphalt content /% | Actual measurement | T0726 | |

| Oversize particle (>31.5mm) content /% | 10 | T0312 | |

| Variability of 0.075mm passing rate /% | ±2 | T0301 or T0327 | |

| Variability of 4.75mm passing rate /% | ±5 | T0301 or T0327 | |

| Asphalt in RAP | Penetration (25, 5s,100g) (0.1mm) | Actual measurement | T0604 |

| Softening point (R&B) /℃ | Actual measurement | T0606 | |

| Ductility (15T) /cm | Actual measurement | T0605 | |

| Coarse aggregate in RAP | Needle-shaped and flaky particle content /% | 20 | T0312 |

| Crushing value /% | 30 | T0316 | |

| Adhesion to asphalt | 3 | T0616 | |

| Fine aggregate in RAP | Angularity /s | Actual measurement | T0345 |

| Sand equivalent for particles smaller than 2.36mm | 55 | T0334 |

It should be noted that if the RAP aggregate itself does not meet the requirements, while the overall aggregate quality meets the requirements after mixing with new aggregates, it can still be used. This demonstrates the flexibility of RAP quality requirements in practical applications.

Types of Asphalt Recycling Plant

Based on the working principles, structural features, and recycling methods, asphalt recycling equipment can be primarily classified into hot recycling equipment and cold recycling equipment, stationary recycling equipment and mobile recycling equipment.

For large-scale projects, stationary hot recycling device can be prioritized to ensure the recycling effect. For small-scale/highly mobile projects, mobile cold recycling equipment is more suitable.

1. Hot asphalt recycling Plant & Cold Asphalt asphalt recycling plant

| Items | Hot Asphalt Recycling Plant | Cold Asphalt Recycling Plant | |

|---|---|---|---|

| Working Principle | Softens the old asphalt, removes impurities, and then mixes it with new asphalt or recycling agents to restore its performance | Softens the recycled asphalt, removes impurities, and then mixes it with new asphalt or recycling agents to restore its performance | |

| Structural Features | Equipped with heating devices, mixing devices and control systems | Consisting of crushing devices, screening devices, and mixing devices | |

| Application Scenarios | Suitable for high asphalt performance requirements and fewer impurities in recycled asphalt situations. | Ideal for situations where there are more impurities in the crushed asphalt or where higher recycling speeds are required. | |

2. Stationery Recycling Plant & Mobile Recycling Plant

| Items | Stationary Recyclers | Mobile Recyclers | |

|---|---|---|---|

| Structural Features | Installed in a fixed location, usually with large processing capabilities and a high degree of automation | Mounted on vehicles, offering mobility and allowing asphalt recycling operations at different locations | |

| Application Scenarios | Suitable for large-scale pavement maintenance and repair projects that require continuous and efficient asphalt recycling | Ideal for small-scale pavement maintenance and repair projects, alao situations that require frequent mobile operations | |

Structure of Asphalt Recycling Plant

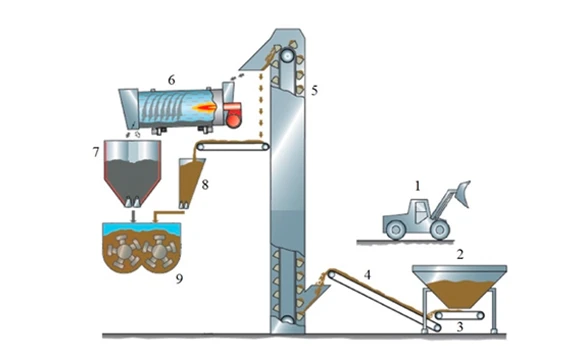

6. Dryer; 7.Storage Bin; 8. Weighing Hopper; 9. Mixer

System Synergy of Asphalt Recycling Plant

The synergistic effect of various systems is crucial in the operation of asphalt recycling equipment. Specifically:

1. Crushing and Screening System

It controls the particle size of the RAP, laying the foundation for subsequent recycling processes.

2. Thermal Recycling System

Ensures the full softening and recycling of aged asphalt by precisely controlling heating temperature and mixing time.

3. Additive Supply System

Accurately measures the amount of additives to ensure stable performance of the recycled asphalt mixture.

4. Flue Gas Treatment System

Effectively purifies harmful gases and dust generated during the recycling process to protect the environment and the health of operators.

More Info About Asphalt Recycling Plant System

Working Principle of Asphalt Recycling Plant

Working Steps:

1. Crushing and Screening

The asphalt recycling equipment first crushes and screens the RAP to obtain aggregates and asphalt mixtures that meet the requirements.

2. Preheating and Drying

The aggregates and asphalt mixtures are sent to a heating device for preheating and drying to remove moisture and impurities in RAP.

3. Mixing and Stirring

The preheated RAP is mixed with new asphalt, recycling agents, and additives in a specific proportion and stirred at high temp to ensure the good pavement performance.

4. Paving and Compaction

The recycled asphalt mixture undergoes paving, compaction, and other construction techniques to obtain the recycled asphalt pavement.

1. Containerized Asphalt Plant

Foundation-free, Quick installation, Long service life, High resale value.

2. Asphalt Mixing Plant JJW Series

Energy efficiency, Recycling asphalt system optional, Vertical drying tower; Hot mix plant.

Asphalt Recycling Plant VS. Virgin Asphalt Plant

Asphalt recycling plants and virgin asphalt plants differ significantly in several aspects, primarily in terms of structure, components, working principles, and applicable scenarios.

| Items | Asphalt Recycling Plant | Virgin Asphalt Plant | |

|---|---|---|---|

| Structure | The more complex structure requires extra considerations for processes such as crushing, screening, heating, and recycling of reclaimed RAP | With a relatively simple structure that mainly comprises aggregate bins, bitumen tanks, mixer, and control systems | |

| Components | Using specialized components such as crushers, screeners, hot air furnaces, recycling agent addition devices, and flue gas purification systems to meet the recycling requirements of RAP | Includes components like aggregate bins, bitumen tanks, and mixing equipment | |

| Working Principle | RAP undergoes crushing, screening, and heating before being mixed with new bitumen, recycling agents, and additives so as to reuse the aged asphalt | Mixes virgin aggregates with new bitumen in specific proportions to produce new asphalt mixtures | |

| Applicable Scenarios | For both new pavement construction and the maintenance and repair of old pavements. Especially works in old pavement renovation projects (on-site recycling & reuse of RAP) | Primarily used for asphalt pavement construction of new highways and urban roads | |

| Economic Benefits | Through the recycling and reuse of recycled asphalt, asphalt recycling plants can save considerable raw material costs and reduce waste disposal expenses | The costs of virgin asphalt plants are relatively higher, due to the raw material, processing, and environmental treatment costs | |

Advantages of Asphalt Recycling Plants

The advantages of asphalt recycling plants are manifested in multiple aspects, including environmental protection, resource conservation, and operational costs.

1. Environmental Protection

Asphalt recycling plants significantly reduce the environmental pollution caused by waste asphalt pavement materials. By recycling and reusing recovered RAP (Recycled Asphalt Pavement), the accumulation and landfilling of large quantities of waste pavement materials are avoided, thereby minimizing the occupation and waste of land resources. Simultaneously, harmful gases and dust potentially generated during the recycling process are purified through the flue gas treatment system before being emitted, drastically reducing pollution to the atmosphere and water system.

2. Resource Conservation

Asphalt recycling plants enable effective resource conservation and circular utilization. Aged asphalt and aggregates in RAP, after undergoing recycling treatment, can be reapplied in the construction of asphalt pavements, substituting for the mining demand of some new asphalt and aggregates. This not only contributes to conserving limited natural resources but also reduces dependence on raw material markets, carrying profound strategic significance.

3. Operational Costs

From the perspective of operational costs, asphalt recycling plants also demonstrate considerable economic benefits. Although their initial investment is relatively high, they can utilize RAP on-site for recycling production, eliminating the transportation and procurement costs of raw materials. Additionally, the production cost of recycled asphalt mixtures is typically lower than that of brand-new asphalt mixtures, further reducing the maintenance and repair costs of pavements. Over the long term, the comprehensive cost advantage of asphalt recycling plants will gradually become prominent.

How To Choose Suitable Asphalt Plant

Future Prospects of Asphalt Recycling Equipment

Asphalt recycling equipment is a crucial technical tool for achieving the circular utilization of asphalt pavement materials. With the global increasingly emphasis on sustainable development and environmental protection, the development prospects of asphalt recycling equipment are extremely promising.

Technological Breakthroughs

1. Rejuvenator Development

Researchers have successfully developed various efficient and environmentally friendly rejuvenators. These rejuvenators significantly enhance the performance of recycled asphalt, providing strong support for the recycling of asphalt pavements.

2. Equipment Intelligence

By incorporating advanced control systems and sensor technology, asphalt recycling equipment has achieved automated and precise production process control. This not only improves production efficiency but also reduces energy consumption and emissions.

3. Flue Gas Purification Technology

New-generation flue gas treatment systems effectively remove harmful gases and dust generated during the recycling process, ensuring the environmental friendliness of the recycling operation.

Market Demand

As global investment in infrastructure construction and maintenance continues to increase, the demand for asphalt pavement repair and renovation is also growing strongly. This provides a vast market opportunity for asphalt recycling equipment. Especially in developing countries such as India and Southeast Asian nations in Asia, Nigeria and Kenya in Africa, and Brazil and Mexico in South America, the acceleration of urbanization and the continuous improvement of road networks will further promote the growth in demand for asphalt recycling equipment.

Current Investment Value of Asphalt Recycling Plant

From a cost-benefit perspective, asphalt recycling equipment exhibits significant investment value, mainly in the following aspects:

1. Reduced Transportation Costs

RAP (Recycled Asphalt Pavement) can be recycled and utilized on or near the construction sites, which greatly reduced the related transportation expenses, lowered the overall project cost, and enhancing the construction efficiency.

2. Notable Long-term Economic Benefits

The use of asphalt recycling equipment extends the service life of pavements, reduces the frequency of repair and maintenance, and consequently lowers the life cycle cost of roads. The accumulation of these long-term benefits further highlights the investment value of the equipment.

3. Enhanced Market Competitiveness

In the current market, products that are environmentally friendly, energy-efficient, and highly effective are highly preferred. Asphalt recycling equipment is one of the representative products that align with these market trends. Introducing this equipment can enhance the market competitiveness of business owners and project contractors, assisting them in expanding their market share.