What is Bitumen Tank?

Bitumen tank is a sort of industrial equipment specially designed for storing and transporting liquid bitumen and its mixtures with excellent structural strength and durability. Relying on the high-strength and highly corrosion-resistant metal materials used, bitumen tanks always have stable performance even in high temperatures or corrosive environments.

CONTENTS

Main Roles of Bitumen Tank

1. Storage of Bitumen

Large capacity design and advanced sealing technology not only ensure safe storage of bitumen but also effectively prevent any possible leakage and external contamination, meeting the requirement of bitumen storage tanks specifications. This makes bitumen tanks the ideal choice for the storage of bitumen.

2. Transportation of Bitumen

Whether by road, rail or waterway, bitumen tanks deliver bitumen to its destination in a stable and efficient manner. This mode of transport enhances logistical efficiency and meanwhile significantly reduces the losses that can occur during transit. That’s why bitumen tanks occupy an important position in the whole transport sector.

Types of Bitumen Tanks

The diverse range of bitumen tanks can cater for the bitumen storage needs of different businesses.

1. Fixed and Mobile

In terms of mobility, there are fixed bitumen tanks and mobile bitumen tanks. The former can be firmly installed in the construction site, suitable for long-term storage, while the latter featuring lightweight and movability can meet the temporary or short-term storage needs, especially suitable for users who need to change their workplace frequently.

2. Horizontal and Vertical

Horizontal bitumen tanks and vertical bitumen tanks are divided by structural form. The former can be placed horizontally and has a large storage capacity, making it suitable for large-scale storage, while the latter needs to be installed vertically and can save floor space, so it is suitable for space-limited scenarios.

There are also bitumen tank container. Designed in combination with standard containers, they are easy to transport and stack, and hence are applicable to frequently moving scenes.

3. Direct Heating and Thermal Oil Heating

In accordance with the heating method, bitumen tanks are divided into the direct heating ones and thermal oil heating ones. The former can directly and efficiently heat bitumen, but the temperature control requirements are higher, whereas the latter are indirectly heated by thermal oil, which allows for more accurate temperature control, therefore suitable for users who require high-quality bitumen.

4. Storage-specific and Transport-specific

By purpose of usage, bitumen tanks can be further sub-divided into storage-dedicated bitumen tanks and transport-dedicated bitumen tanks. The former focuses on long-term, stable bitumen storage, while the latter is specially designed for bitumen transport to ensure the safety and stability during transportation.

5. Small, Medium and Large

Capacity is the most common way to classify tanks, typically measured in liters, gallons, or cubic meters. There is no universal standard, though following figures can give you a rough perception: up to 25,000 liters (small), 25,000 liters to 80,000 liters (medium), over 80,000 liters (large).

Besides capacity, mobility is a factor to consider when it comes to the bitumen tank size. Skid-mounted tanks for easy transport might be considered "small" even with a decent capacity, and permanently installed tanks would likely be considered "large" regardless of specific capacity.

Tell Us What Type of Bitumen Tank You Would Like?

Structure and Characteristics of Bitumen Tanks

1. Components of A Bitumen Tank

The main components of an asphalt tank include tank, heating system, insulation, level gauge and safety devices.

- Tank: Responsible for storing bitumen, with high strength and good sealing to prevent leakage and impurity intrusion.

- Heating System: Controls the heating temperature to keep the bitumen in the best working condition to fulfil the construction demand.

- Insulation layer: Advanced materials and designs are used with the aim of locking the heat, keeping the bitumen at a stable temperature and improving efficiency.

- Safety devices: Including explosion-proof, temperature control and emergency stop, etc. to ensure the safety of equipment and personnel.

2. Factors Affecting The Capacity of Bitumen Tank

The capacity of bitumen container is affected by factors such as tank size, thickness of insulation layer and efficiency of heating system.

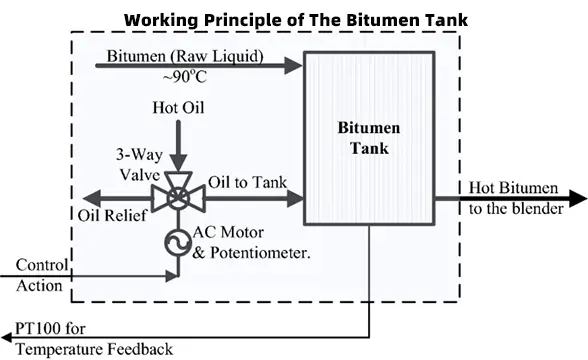

3. Working Principle of The Bitumen Tank

The bitumen storage tank utilizes organic heat carrier (thermal oil) as the heat transfer medium, with coal, gas, or oil-fired burners as the heat source. The bitumen is heated to the required temperature through forced circulation by a thermal oil pump. With careful design and configuration, the heated bitumen is smoothly transported from the storage tank to the construction equipment or storage facilities.

1. Heating System: Typically located at the bottom of the tank, the heating system raises the bitumen to the desired temperature, achieved through direct combustion, thermal oil circulation, or electric heating.

2. Temperature Control: Temperature control is achieved through temperature sensors and control systems, ensuring precise regulation by operators to maintain optimal heating conditions.

3. Insulation: Insulation layers surround the tank, minimizing heat loss and aiding in the stabilization of internal temperatures.

4. Mixing System: Some bitumen tanks may feature mixing systems to prevent sedimentation and ensure uniform heating and mixing of the bitumen.

5. Safety Features: Safety valves, pressure gauges, and emergency shutdown mechanisms are employed to ensure safe operation and prevent overpressure situations.

6. Accessories: Additional components such as pumps, valves, and temperature monitoring devices contribute to the efficient operation and maintenance of the bitumen tank.

Application Scenarios of Bitumen Storage Tank

1. Asphalt Mixing Plant

Bitumen tank is one of the core components of asphalt mixing equipment and is used to properly store bitumen on-site, continuously supplying the pavement material producing device with the required base bitumen to enable the production of high-quality asphalt mixtures.

2. Bitumen Refining and Distribution

Bitumen tanks are the key to receiving, storing and delivering bitumen, thereby facilitating a smooth and efficient bitumen supply chain.

3. Building and Waterproofing

Bitumen is a key material, whether for paving roads, building car parks or waterproofing roofs. Bitumen tanks provide the required bitumen at the construction site at any time to make sure the construction progress and quality. Especially when building roofs, this sort of tanks are a convenient storage and supply solution for efficient waterproofing projects.

Bitumen Tank Cost Analysis

Taking following factors into account is set to help the investor make an informed decision and ensures that the purchase and use of asphalt tanks is economically viable.

1. Bitumen Tank Price Composition

The price of bitumen tanks is mainly determined by factors such as manufacturing cost, material cost, technological added value, brand influence and market positioning. Among them, manufacturing costs include direct production costs and indirect costs, such as labour costs, equipment depreciation and maintenance costs. Material costs are related to the quality and cost of raw materials used, like steel and insulation materials. Technical added value is reflected in product design, functional innovation and performance.

2. Other Factors Affecting The Price

In addition to the above price components, market demand fluctuations, production scale, changes in raw material prices, international trade policy adjustments, as well as environmental protection and safety standards to improve the price of asphalt tanks will also impact.

3. Initial Investment and Operating Costs

It is necessary to consider the initial investment in acquisition costs and installation, commissioning, training and other additional costs. Ongoing expenditures such as routine maintenance, energy consumption, insurance investment and personnel management should also be considered in the course of operation.

4. Return on Investment Analysis

An ROI analysis evaluates the service life, residual value, maintenance intervals and timing of replacement of an asphalt tank, and calculates its potential benefits in terms of increasing productivity, reducing costs and meeting market demand.

Bitumen Tank Maintenance and Usage Precautions

1. Bitumen Tank Cleaning Procedure

- Regularly remove the dirt and oil stains on the exterior of the tank to maintain a neat appearance.

- Remove sediments inside the tank regularly to prevent impurities and residues from affecting the quality of bitumen.

- Choose appropriate cleaning agents and tools to avoid damage to the tank.

2. Inspection

- Regularly check the integrity of the tank, sealing performance and effectiveness of safety devices.

- Calibrate the accuracy of the level meter, thermometer and pressure gauge and other key instruments to ensure real-time grasp of the working condition.

- Problems found in a timely manner to take measures to ensure the safe and reliable operation.

3. Repair and Renovation

- Repair measures should be taken immediately once the tank cracks, deformation or corrosion and other problems are spotted.

- Refurbishment works should be carried out for the deteriorated bitumen tanks, including the replacement of lining, update insulation materials, upgrade the safety system.

- Repair and refurbishment aim at restoring the performance and extending their service life.

4. Precautions for Use

- Relevant operating procedures and safety standards should be complied to ensure the safety of personnel and equipment.

- Avoid unsafe behaviour such as over-pressure and over-temperature to keep them in stable and efficient working condition.

- Implement regular maintenance to give full play to the maximum value.

Conclusion

The bitumen tank industry stands at a crossroads of opportunity and challenge presented by emerging technologies. Advancements in automation and intelligent systems promise to enhance the convenience and safety of bitumen tank operation. However, these advancements will necessitate a higher level of sophistication in both production and maintenance practices. To navigate this evolving landscape, the industry must embrace continuous innovation and adaptation to meet the shifting demands of the market and overcome potential hurdles. As technology progresses and industry needs expand, the bitumen tank industry is poised for significant growth and a broader development trajectory.