What Is Asphalt Plant

Asphalt plants, also called asphalt mixing plants or hot mix plants, are equipment that can combine aggregates and bitumen to produce asphalt mix for road paving. Mineral fillers and additives may be required to add to the mixing process in some cases. The asphalt mix can be widely applied for the pavement of highways, municipal roads, parking lots, airport expressway, etc.

While there are a variety of classification standards concerning asphalt plants, some representative types, like batch mix, drum mix, mobile and recycling, are widely comprehended and accepted. Categorization of asphalt plants is elaborately summarized in the article Types of Asphalt Plant.

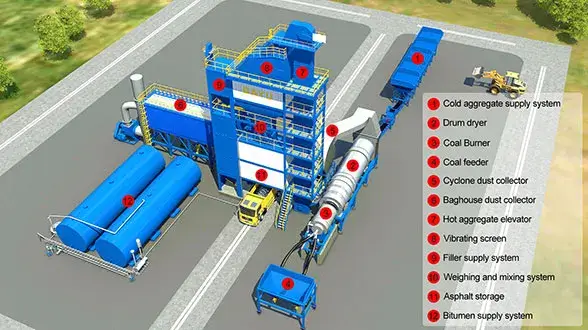

Asphalt Batching Plant

1. Definition

Asphalt batching plant is a set of equipment that produces final mixture batch by batch, and characterized by intermittent pauses between batches. Due to the accurate weighing system for dosing the aggregates, bitumen and other admixtures, the products of it are of high quality. There is a time interval between two mixing batches because of the mixer, so it's also known as the discontinuous or intermittent type.

In asphalt batching plants, the mixer with double arms and paddles means the mixing quality is undoubtedly better when compared with continuous plants because it is forced.

2. Working Process

How Does An Asphalt Batching Plant Work?

- Aggregates are fed by belt conveyor from the cold feeders to a rotary drying drum where the moisture is removed.

- It is then elevated to a set of screens where it is divided into several component sizes and stored in hot aggregate temporary storage bins.

- These aggregates are then correctly proportioned into a weigh hopper.

- It is introduced into a pug mill and mixed for a specified amount of time.

- Liquid bitumen is introduced at the proper time and the combination is then mixed for the required time.

- The pug mill gate opens at the end of this cycle and the finished asphalt mix is discharged directly into a waiting truck or or the special holding silo.

3. Advantages

- Batch mix plants manufacture a very high-quality finished product due to the accurate measurement of each batch produced.

- The intermittent production process enables them to easily switch back and forth between different mix specifications if necessary.

- In batch plants, the pug mill uses arms with paddles attached to them, thus creating a forced or physical mixing of the components.

- In most cases, they come with baghouse dust collectors. The dust generated during the whole process could be captured, leaving the surrround environment not polluted that much.

Asphalt batch mix plants make small accurate batches of asphalt mixture through a process that is repeated over and over until the total tonnage for a project has been manufactured. Beginning from hot aggregate weighing, and ending with discharging action completed, one whole batch usually takes about 40 ~ 45 seconds. The mixing time can be lengthened or shortened and thereby the mixing quality can be varied, depending on the type of material being produced.

By the way, the greatest weakness of batch mix type equipment is that about 30% of its time is spent waiting on bins to weigh up, the mixer to empty and so.

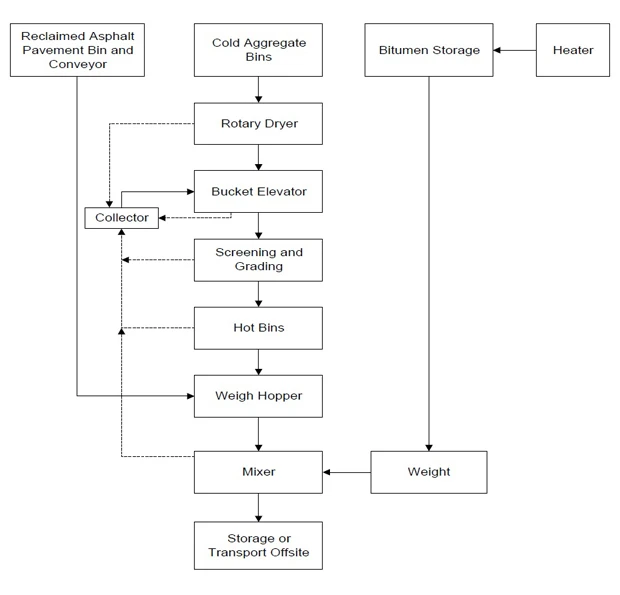

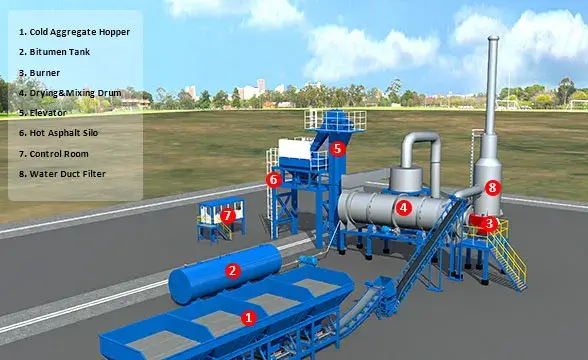

Asphalt Drum Mix Plant

1. Definition

Asphalt drum mix plant is a facility that is featured with a continuous paving material manufacturing process without the interval pauses. It's more timesaving and efficient, so compared with its counterpart, the lower-cost equipment will be an ideal choice if the quality standard of paving materials is not pretty high.

Drum mix plants prepare the asphalt mix through a continuous process, so they often require the use of temporary storage silos in an effort to avoid downtime due to the final mixture not dealt with in time.

2. Working Process

How Does An Asphalt Drum Mix Plant Work?

- Flow meters and calibrated feed belts are used to measure the liquid bitumen and cold aggregates, helping ensure they proportionally enter the dryer/mixer.

- Cold aggregates are then conveyed to the dryer/mixer where the first half is dedicated to remove moisture.

- The correct percentage of liquid bitumen is injected and the resultant material is thoroughly mixed into the other half of drying drum.

- The final asphalt mix is discharged into the waiting truck or the special holding silo.

Almost all asphalt drum mix plants used to be of the parallel flow type, with the aggregate and the burner flame travelling down the chamber in the same direction. The counter-flow technology has prevailed these years, with the aggregate travelling down the chamber toward the burner flame.

Due to the continuous production property, to avoid downtime caused by the excessive final mix that is not delivered offsite immediately, a small temporary storage bin is sometimes a must. To control pollution, the drumming equipment is often equipped with water dust filters or baghouse collectors.

3. Advantages

- By eliminating most of the steps taken by an asphalt batching plant to produce mix, a drum plant is able to do its job more economically as the rhythm of production is not broken into batches.

- It is a continuous process that creates a homogeneous mixture that can be manufactured at a high rate.

- Since there are no mixing tower or elevators, the system is therefore considerably simplified, with a consequent reduction in the cost of maintenance.

Due to the nature of their design, asphalt drum mix plants are limited to conduct one mix recipe at a time, so the continuous AMPs are the correct facilities for the companies who are not concerned with switching back and forth to various recipes.

Mobile Asphalt Plant

1. Definition

Mobile asphalt mixing plant is a batching or continuous asphalt producing equipment that has its mobility performance improved by being designed to be more compact and mounted with the automobile chassis. It is an ideal facility to carry out small- or medium-scale road construction projects, especially those requiring the equipment to move from one place to another frequently.

That is to say, the portable feature allows you to carry the mobile mixing factory along with your bandwagon wherever you go for the next project. In terms of maneuverability, mobile asphalt plant as a category can be further subdivided into semi-mobile, mobile, and super-mobile genre. What's more, they all have their most applicable regions around the world. For example, despite the fact that portable plants are easy to deploy in the mountainous regions or somewhat confined areas, for those road-building projects with the features of long distance and narrower pavement, mobile or hypermobile plants seems more suitable than semi-mobile plants, simply because they can leverage their's unparalleled advantages, such as fast transportation, ease of reassembly, and rapid production restart, to the full. The hyperportable hot mix plants, able to reenter into production within only some hours after they settle dowm at the new places with no need of cranes, much laborforce, and civil work. So convenient that the super-mobile AMP has prevailed in the South America since it came out. To learn more about this issue, this blogpost Mobile Asphalt Plants For Sale deserves your clicks.

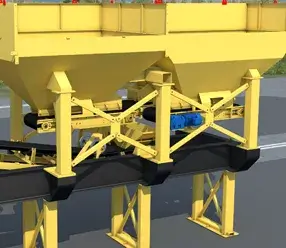

Super-mobile Asphalt Mixing Plant In Transit and Main Components

2. Advantages

- Compact structure leads to less land footprint, also making it capable to be placed in a narrow or confined area.

- Highly mobile, convenient for transportation and relocation due to four main modules, and each with a mobile chassis.

- Ease of reinstallation, and can restart production with less trouble to handle.

- Especially applicable to those projects demanding the plant to move frequently.

- Low initial investment and highly cost-effective.

It's fairly easy to choose between portable and stationary once you know the answers to a couple of questions: Do you need to move your plant? If so, how often will it be moved?

One incontrovertible rule is that portable asphalt plants cost substantially more than their stationary brethren. So those companies who need to move plant once every few years should consider buying a skid-mounted plant with flexible wiring, like SO cord, equipped with quick disconnects.

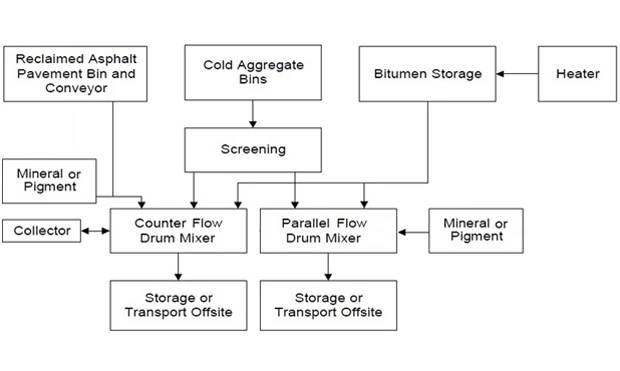

Asphalt Recycling Plant

1. Definition

Asphalt recycling plant is equipment well designed to combine reclaimed asphalt pavement (RAP), hot fresh aggregate and filler to produce new finished mixture that can be used for driveways, roadway and parking lot repairs. Recycling of pavements can offer engineering, economic and environmental benefits.

The process involves off-site processing and mixing of the RAP with a predetermined proportion of specially formulated bitumen emulsion. The mixture is then transported to the job site and placed in a manner similar to conventional hot mix asphalt.

2. Working Process

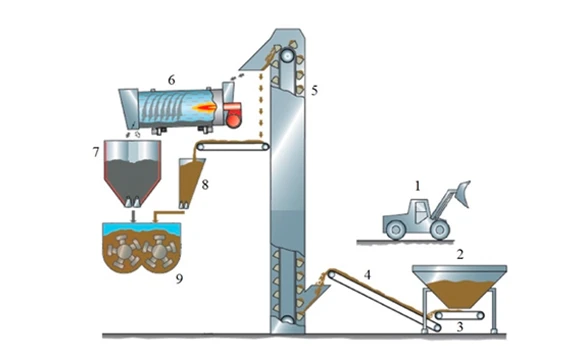

6. Dryer; 7.Storage Bin; 8. Weighing Hopper; 9. Mixer

3. Advantages

- By applying asphalt recycling technology, the use of new pavement materials can be reduced by recycling reclaimed asphalt pavement, achieving lower cost and lower environmental impact than conventional methods.

- Asphalt fumes and harmful gas generated in the production process can be recycled into drying drum and burn again, reducing exaust emission.

- Recycled asphalt proportion could reach up to 50%, reducing the production cost to a large degree.

Actually, recycled asphalt mix can be divided into recycled hot mix asphalt and recycled cold mix asphalt. Based on the road surface pavment process, cold on-site recycling (also named cold in-place asphalt recycling, shorted for CIR), cold central plant recycling, hot on-site recycling (also named hot in-place recycling, shorted for HIR), and hot central plant recycling are all fall under this issue.

HIR is unable to correct structural failures and can only be used as treatment to road surface distresses like cracking, raveling, low friction values and distortion. CIR is also considered not to have the ability to treat the underlying structural problems.

Compared to conventional paving, a road rehabilitated cold central plant recycling delivers a cost savings of 25-50%. Moreover, compared to cold on-site recycling, cold central plant recycling can realize better process control of recycled materials, significant structural improvements without changing the geometry of the existing pavement and the utilization of lower-cost recycled materials.

You may be interested in the prices of hot recycled plants, then Asphalt Recycling Plants For Sale is the right place to find answers yourself.

FAQ

1. How much does an asphalt plant cost?

Ranging from $100,000 to $5,000,000, the price of asphalt plant highly depends on its production capacity and the type. As a general rule, the batch mix type has more functions, and it is more complicated than a drum mix plant and hence costlier to own and operate. Drum plants are usually cheaper to own and maintain. Given the same production capacity, the prices of batch mix asphalt plants are commonly higher than their counterpart, portable asphalt plants cost substantially more than their stationary brethren. Please note that the perk of a batch plant-like best quality of mix asphalt will outrun the cheaper cost of drum plant. Tap on How Much Does An Asphalt Plant Cost to get more.

2. How is the return on investment in asphalt plant?

The purchase of asphalt mixing plant actually only accounts for less than 2% of the entire investment. The procurement cost of aggregates and bitumen accounts for more than 75% of the total cost, followed by fuel, which accounts for about 12%. In other words, a set of asphalt mixing plant can bring unexpected return on investment by reducing the cost of fuel and raw materials while ensuring the output and quality of final asphalt mixture.

3. Do you need a new asphalt plant or a used one?

Both have distinct advantages over the other. The advantages of a new plant are obvious: It's new, and comes with full factory support. Then, most factories will assist you in the set-up, debugging and trial production of the equipment. Plus, they are willing to help you train operators upon your demand. This is a real plus for companies new to the world of asphalt plants. Used plants can be considerably less expensive. Find one that is offered direct from the owner or his primary broker. In general, try to find out as much information as possible about a particular plant if it catches your eye.

4. Batch mix and drum mix asphalt plant, which one to choose?

Both of them have strengths and weaknesses, just as the following table shows.

| Asphalt Batch Mix Plant | Asphalt Drum Mix Plant | |

| Advantages | All Ingredients Are Acurately Weighed | Compact Structure, Convenient for Transportation |

| Able to Add Various Admixtures | Less Land Footprint | |

| Monitor the Oil-stone Ratio in Real Time and Change Oil-stone Ratio during Operation | Relatively Low Operating Cost | |

| Most Adopt Baghouse Dust Collector, Great Environmental Performance | Low Investment Cost and High Cost-effectiveness | |

| High Degree of Intelligence in Control System | Particularly Suitable for Projects in Rural Areas | |

| High Quality of Finished Mixture | ||

| Applicable to Large-scale and High-grade Road Construction Projects | ||

| Disadvantages | More Land Footprint | No Acurate weighing and Precise Screening |

| Higher Initial Investment | Can't Add Various Admixtures | |

| High Maintenance and Operation Cost | Unable to Monitor and Accurately Change Oil-stone Ratio during the Operation | |

| Complex Structure, Not Easy to Master Quickly | Simple Dust collectors and Relatively Less environmental-friendly | |

| Lower Quality of Finished Mixture |

Your ultimate option shall be determined by the actual conditions of projects the AMP will serve. If the targeted project is large in scale, high in grade, needs to change mix design in operation, batch mix factory is supposed to be a good choice. Conversely, you should choose drum mix type if the project is small-scaled and low-grade.This is just a simple advice, and more comparison between the two major types, including working principles, structure, application scenes, and prices, are all detailedly explained in Asphalt Batch Mix Plant VS Asphalt Drum Mix Plant.

5. Where to buy a higher performance-to-price ratio asphalt plant?

The answer is China. For Some reasons. As Top 5 Asphalt Plant Manufacturers In The World suggests, those shiners like Ammann, Benninghoven, Astec, own sophisticated manufacturing and management experience, as well as the rich techniques accumulated in long history, Yet due to the high human resource cost and corporation running cost, Asphalt plants manufactured by them are so costly that many buyers from developing areas need to make great efforts to afford them, or even can't burst out such ideas. China is the right place to turn to. Other than that the prices of hot mix plant products are two or three times lesser than those of European and American peers, the gap in quality is being narrowed. If you intend to purchase a cost-effective pavement material production plant, Tips for buying asphalt plants from China is highly recommended to you.