Top 3 Best-selling Asphalt Plants In The World

Asphalt plant is a facility that is specifically used to mix aggregates and bitumen to manufacture final asphalt paving material. As per the requirement, some fillers and additional agents could be added to the mixing course. The asphalt mixture can be widely applied for the pavement of expressways, urban roads, grade highways, etc.

There are hundreds of asphalt plants for sale on the market, but the best-selling ones in the world mainly fall into 3 categories, asphalt batch mix plant, asphalt drum mix plant, and mobile asphalt plant. Choosing the category is the first step to buy the right hot mix equipment.

6 Factors To Consider When Buying An Asphalt Plant

1. Quality criteria of the final mix

2. Quantity of asphalt mix which should match with the project scale

3. Geographical conditions of the equipment's job site

4. Environmental requirement of your local authority

5. Whether frequent relocation is needed or not

6. Your budget

For your reference, we'll present you with the top 3 asphalt plants throughout the world in sequence, and show you the common-seen mixing facility types in different countries and areas.

1. Asphalt Batch Mix Plant

Asphalt batch mix plant, also called asphalt batching plant or discontinuous asphalt plant, is a facility that utilizes a batch mixer to blend aggregates and bitumen to produce asphalt mix batch by batch. Due to the precise measurement imposed on each ingredient, it can guarantee high-quality HMA output.

| Features | Batch mix, interval pauses between batches |

| Advantages | Precise batching, accurate weighing, high-quality end product |

| Capacity | 60t/h ~ 500t/h |

| Price Range | $100,000 ~ $1,000,000 |

| Applicable Regions | Europe, Russia, Japan, Korea, China, Australia, etc. |

This type of paving material manufacturing equipment can be seen everywhere in the world, but more commonly in the maturer economies, like Europe, Russia, Japan, Korea, China, Australia, etc. There are many reasons for it. For instance. Some governments like Russia rigidly require the aggregate grading, and at least 4 layers of vibrating screens shall be available; Some countries have been implementing high-quality final product standards. To cater to such administration demands, the HTA batching station is the ideal choice amongst so many options.

In other areas, like Southeast Asia and Africa, there are also a certain number of batching stations erected, since high-grade roads, like expressways, usually need batch type of mixing equipment to match with and make the high-quality paving materials.

2. Asphalt Drum Mix Plant

Asphalt drum mix plant, also known as continuous asphalt plant, is a plant that can blend aggregates and bitumen to manufacture asphalt mix continuously. It features a drying drum that combines the function of drying and mixing together. Compared with the asphalt batching plant, It's more time-saving and efficient due to no interval pauses.

| Features | Continuous production |

| Advantages | Compact structure, high efficiency, lower initial investment |

| Capacity | 8t/h ~ 200t/h |

| Price Range | $50,000 ~ $300,000 |

| Applicable Regions | South America, North America, Southeast Asian, etc. |

In the whole American continent, continuous drum mixers are well-accepted and hot selling ever. ADM and Astec, two top-class manufacturers in the USA, are specialized in producing continuous mixing plants, which occupy a far larger proportion of their products. There is a possibility that their drum mix equipment complete the aggregate weighing and screening before allowing it to enter the multi-function drum, which ensures high quality of the final mix.

South America also sees drum mixer dominating on the market. That's because a lot of infrastructure building needs to be conducted in rural areas. Demands on generic paving materials are huge, and high efficiency is also attached importance with drum mix HMA manufacturing facilities can satisfy these requests fully.

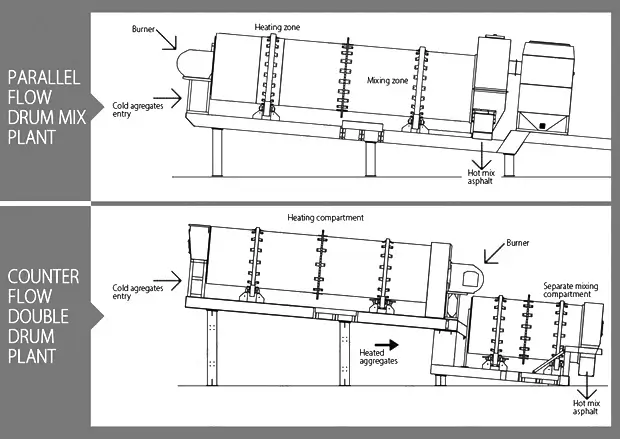

Drum mix factories can be divided into parallel-flow type and counter-flow type.

2.1 What Is Parallel-flow Asphalt Plant?

Parallel-flow asphalt plant is a set of equipment used to heat aggregates and mix them with bitumen to produce the final asphalt mix. What makes it different is that drying and mixing take place in a single drum, and the direction of the burner flame and aggregate flow is parallel.

This feature leads to a result that it's less effective and more fuel-consuming. Plus, there are no methods to measure the temperature of hot aggregates in this type.

2.2 What Is Counter-flow Asphalt Plant?

Counter-flow asphalt plant is a paving material manufacturing facility that performs drying and mixing processes in a separate drum, and the aggregates flowing direction is opposite to the burner flame.

These characteristics not only ensure the heating of aggregates is done with minimum fuel consumption, but ensure the bitumen never exposes itself to extreme temperatures because the bitumen is nowhere in contact with the burner flame. Also, measuring the temperature of hot aggregates is made possible in this type of continuous HMA producing equipment, which can be controlled before the aggregates move to the mixing zone.

3. Mobile Asphalt Plant

Mobile asphalt plant, also called portable asphalt plant, is a batch mix plant or drum mix plant that can be split into several mobile modular and mounted on the automobile chassis to achieve prompt relocation, reinstallation, and production recovery. It is an ideal facility to carry out small- or medium-scale road construction projects, especially those requiring the equipment to move from one place to another frequently.

| Features | Mobilizable |

| Advantages | Ease of relocation, reassembly, fast production restart |

| Capacity | 10t/h ~ 400t/h |

| Price Range | $60,000 ~ $550,000 |

| Applicable Regions | South America, Africa, middle-east, southeast Asia, etc. |

Due to their compact structure, portable hot mix stations are the most fittable for those mountainous countries or confined areas.

Stationary HMA makers, no matter what types they are, can be seen occasionally in Africa, middle-east, southeast Asia, and South America, but in these mountainous countries, mobile ones exert their power well and prevail over other types.

As we say above, the clients from south America prefer drum mix type to batch mix type. In fact, the clients, especially those from mountainous areas, favor drum mix asphalt plants with high degree of mobility, though their production capacity is smaller. Integrated mobile asphalt mixing facilities with a capacity of 20t/h-200t/h are their first choices.

In addition, some road-building projects feature long distance and narrowness, requiring attached construction equipment to move from time to time. Under this condition, procuring a portable factory is a smart choice, wherever you are.

FAQs On Buying Asphalt Plants For Sale

1. How To Choose A Right HMA Machine As A Green hand?

Please bear in mind that the right fit is the best. Where you are is not the decisive factor. Other aspects, like the scale of your project, the quality standard of the road, the budget for buying related equipment, etc, should be also in your thought.

2. Is There More Detailed Comparison Between Batch Mix and Drum Mix?

Both are different in many aspects, ranging from working principle, equipment structure finished mixture to the price. More information please refer to Asphalt Batch Mix Plant VS Asphalt Drum Mix Plant.

3. How Much Is An Asphalt Plant?

It varies so much with the different manufacturers. The gap is pretty huge. Some manufacturers set the price at $500,000 to $4 million, but there are some others who price their products at $23,000 to $1,000,000. As for the equipment itself, the price is mainly up to the capacity, type, configuration, freight, etc. Customization is becoming mainstream in the procurement process, so it's necessary to keep the manufacturer informed about your detailed requirement.

4. What Are The Top Asphalt Plant Brands Throughout The World?

The top brands include Ammann, Marini, Benninghoven, etc. To learn about more, you may be interested in this article Top 5 Asphalt Plant Manufacturers In The World. A fact sheet of the world's top manufacturers and suppliers is listed therein.