Thermal Oil Boiler

Thermal Oil Boiler

- Model: YYW-350Y.Q ~ YYW-1400Y.Q

- Rated Thermal Power: 350kW ~ 1400kW

- Highlights:

1. Excellent thermal conductivity;

2. Precise temperature control;

3. Stable operation, low energy consumption;

4. Applicable to multiple energy sources;

Introduction to Thermal Oil Boiler

Thermal oil boiler is a type of heating equipment that uses thermal oil as the heat carrier. It circulates the liquid phase through a forced circulation pump to transfer heat energy to a boiler for heating equipment. Typically, it consists of a combustion chamber, chimney, thermal oil circulation system, and control system. Thermal oil boilers are widely used in industrial fields that require high temperatures, such as petroleum, chemical, pharmaceuticals, textile dyeing, light industry, construction materials, food, and asphalt heating for road construction.

Model and Parameter

| Model | YYW-350Y.Q | YYW-700Y.Q | YYW-930Y.Q | YYW-1200Y.Q | YYW-1400Y.Q | |

|---|---|---|---|---|---|---|

| Rated Thermal Power (kW) | 350 | 700 | 930 | 1200 | 1400 | |

| Heat Supply (kCal/h) | 300,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | |

| Fuel Thermal Efficiency (%) | 91.8 | 91.7 | 91.7 | 91.8 | 91.8 | |

| Gas Thermal Efficiency (%) | 92.2 | 92.1 | 92.2 | 92.2 | 92.1 | |

| Design Pressure (MPa) | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

| Maximum Operating Temperature (℃) | 320 | 320 | 320 | 320 | 320 | |

| Medium Circulation Volume (m³/h) | 40 | 60 | 100 | 100 | 100 | |

| Furnace Medium Capacity (m³) | 0.18 | 0.6 | 0.7 | 0.8 | 0.85 | |

| Main Pipe Diameter (DN) | DN80 | DN100 | DN125 | DN125 | DN125 | |

| Applicable Fuel | Light oil / Heavy oil / Gas | |||||

| Fuel Consumption | Light Oil (kg/h) | 32 | 64.1 | 85 | 109.6 | 127.9 |

| Natural Gas (Nm³/h) | 38.4 | 76.8 | 102 | 131.5 | 153.7 | |

| Dimensions | Vertical | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal |

| Horizontal | ||||||

| Circulation Pump | Model | WRY80-50-190 | WRY100-65-200 | WRY100-65-230 | WRY100-65-240 | WRY100-65-257 |

| Flow Rate (m³/h) | 40 | 80 | 100 | 100 | 100 | |

| Head (m) | 40 | 40 | 55 | 70 | 80 | |

| Power (kW) | 7.5 | 15 | 22 | 30 | 37 | |

| Oil Injection Pump | Power (kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Main Features of Thermal Oil Boiler

1. Excellent Thermal Conductivity

Thermal oil boilers use thermal oil as the heat transfer medium, exhibiting excellent thermal conductivity for effective heat transfer.

2. High-Temperature Stability

Thermal oil maintains good stability even at high temperatures, making it suitable for industrial and manufacturing processes with high-temperature heating requirements.

3. Precision Temperature Control

Equipped with advanced control systems, our thermal oil furnaces can precisely control and adjust operating temperatures, ensuring a stable heating process.

4. Flexible Energy Source Options

Thermal oil heaters can utilize various energy sources such as light oil, heavy oil, or natural gas, providing flexibility in energy choices for heating.

5. Compact Structure, Easy Installation

Designed with rationality, compact structure, and easy installation, our thermal oil boilers are suitable for diverse industrial environments and layouts.

6. Wide Applications

Widely used in industries like chemical, pharmaceuticals, textile, food processing, etc., our thermal oil heaters meet high-temperature heating requirements in various production processes.

7. Low-Pressure Operation, High Efficiency, and Energy Conservation

Our thermal oil heating systems operate at low pressure and incorporates advanced technologies to achieve efficient energy utilization, promoting energy conservation and environmental sustainability.

Your inquiry will be replied within 24 hours.

Containerized Bitumen Tank

Containerized Bitumen Tank

- Model: 20GP & 40HQ

- Capacity: 20 & 40m³

- Highlights:

1. Containerized design;

2. High transport efficiency and low cost;

3. Strong versatility and high safety;

4. Excellent insulation performance and wide applicability;

Introduction to Containerized Bitumen Tank

Containerized bitumen tank is a specialized equipment designed for the storage and transportation of bitumen. It consists of a steel tank and a frame, with the frame adhering to the container size requirements set by the International Organization for Standardization (ISO). The tank is typically constructed from carbon steel or stainless steel and is coated with a corrosion-resistant layer. It is equipped with heating, insulation, and loading/unloading systems. Widely used in road construction, repairs, and various projects related to asphalt, it proves to be an efficient and reliable solution in the asphalt industry.

Model and Parameter

| Model | 20GP | 40HQ |

|---|---|---|

| Maximum Volume (m³) | 29 | 55 |

| Dimensions (mm) | 6058*2438*2591 | 12192*2438*2896 |

| Insulation Material | Rock Wool | Rock Wool |

| Insulation Thickness (mm) | 50 | 100 |

| Weight (kg) | 6500 | 9500 |

| Heating Method | Direct Heating, Electric Heating, Thermal Oil Heating | |

| Standard Accessories: | ||

| Level Indicator | Mechanical/Electronic | Mechanical/Electronic |

| Thermometer | Mechanical/Electronic | Mechanical/Electronic |

| Ladder | Available | Available |

| Platform | Not Available | Not Available |

| Manhole | Available | Available |

| Pre-assembled Pipeline | As Required | As Required |

| Valves and Accessories | As Required | As Required |

| Optional Accessories: | ||

| Mixer | ||

| *More models can be customized according to user requirements. | ||

Main Features of Containerized Bitumen Tank

1. Containerized Structure

Its appearance and structure resemble standard shipping containers, typically constructed from steel. The structure is robust, suitable for both land and sea transportation. The interior of the tank is often made of corrosion-resistant materials to ensure long-term durability.

2. Flexibility in Capacity

The capacity of the containerized bitumen tank can be customized according to requirements, usually available in various specifications and sizes. This flexibility is beneficial for meeting the bitumen storage needs of different construction sites and projects.

3. Heating System

To address the issue of high viscosity in bitumen at low temperatures, the containerized bitumen tank is equipped with an efficient heating system. This is primarily achieved through methods such as direct heating, thermal oil heating, or electric heating, ensuring that the bitumen maintains proper fluidity during storage and transportation.

4. Insulation Design

In order to prevent bitumen from solidifying due to temperature drops during transportation, containerized bitumen tanks typically incorporate insulation design. This includes the use of insulation materials such as rock wool to reduce heat loss and maintain stable temperatures for the bitumen.

5. Mixing System

Some containerized bitumen tanks are also equipped with a mixing system to ensure the uniform mixing of bitumen, preventing issues related to sedimentation and uneven temperatures.

6. Safety Features

Containerized bitumen tanks are typically equipped with various safety features, including temperature sensors, pressure sensors, safety valves, etc., to ensure safe operations during storage and transportation.

7. High Transportation Efficiency

Due to its containerized form, this bitumen tank exhibits flexible transportation capabilities. It can be conveniently transported to various construction sites or destinations through different modes of transportation, including road, sea, and rail transport.

8. Environmentally Friendly and Low Carbon

Some containerized bitumen tanks designed with modern considerations also prioritize environmental factors. They utilize eco-friendly materials and technologies to reduce adverse environmental impacts, contributing to a low-carbon and environmentally sustainable solution.

Your inquiry will be replied within 24 hours.

[No form id or name provided!]

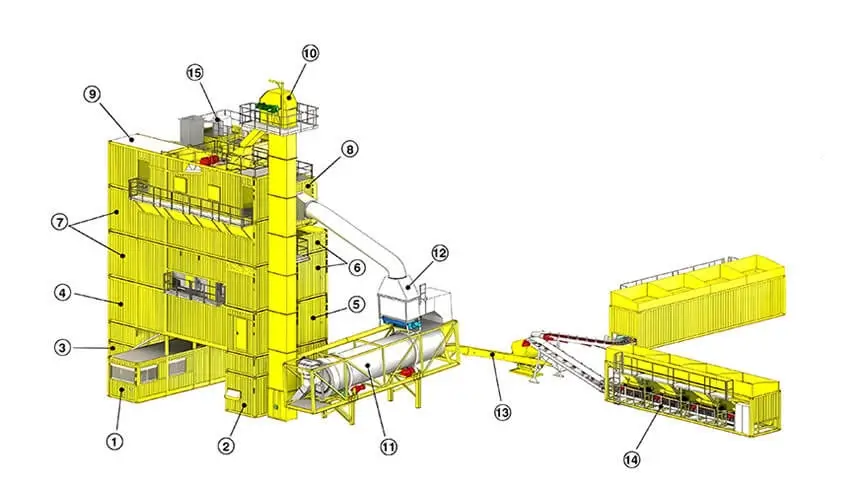

Containerized Asphalt Mixing Plant

- Model: CFB80 ~ CFB400

- Product Capacity: 80t/h ~ 400t/h

- Highlights:

1. Containerized, easy transportation

2. Foundation-free, quick installation

3. Accurate weighing, batch mix, high-quality outputs

4. Long service life, high resale value

Brief Introduction

A Containerized Asphalt Mixing Plant is a portable asphalt batching plant with a modular design, featuring convenient transportation, quick installation, and flexibility. It can effectively mix various asphalt mixtures with cold aggregate feeding system, drying system, screening and mixing system, dust collecting system, and control system through intelligent operation. The containerized design makes it easy to use the plant on different sites, providing convenience for road construction while reducing transportation and installation costs. The CFB series Containerized Asphalt Mixing Plant offers various production capacity models to meet diverse customer requirements.

Technical Parameters

| Model | CFB80 | CFB120 | CFB160 | CFB240 | CFB320 | CFB400 | |

|---|---|---|---|---|---|---|---|

| Capacity (t/h) | 80 | 120 | 160 | 240 | 320 | 400 | |

| Power (kW) | 245 | 305 | 345 | 505 | 660 | 810 | |

| Cold Aggregate Feeders (m³) | 4 x 8 | 4 x 9 | 5 x 9 | 6 x 12 | 6 x 15 | 6 x 18 | |

| Drying Drum (mm) | 6000 x 1500 | 7500 x 1600 | 7500 x 1800 | 8500 x 2000 | 9500 x 2200 | 11000 x 2700 | |

| Hot Aggregate Storage Bins (m³) | 12 | 22 | 36 | 53 | 53 | 70 | |

| Weighing Sensor (kg) | Hot Aggregate | 1000 | 1200 | 1750 | 2250 | 3000 | 4000 |

| Filler | 100 | 250 | 250 | 250 | 400 | 600 | |

| Bitumen | 100 | 200 | 200 | 200 | 400 | 600 | |

| Mixer Capacity (kg) | 1500 | 1500 | 2250 | 3500 | 4250 | 5500 | |

| Bag-house Dust Collector Filtering Area (m²) | 400 | 473 | 489 | 674 | 830 | 1132 | |

| Filler Silo (m³) | 30 | 30 | 30 | 30 | 52 | 75 | |

Advantages

A high-efficiency and high-capacity feature characterizes the containerized asphalt mixing plant. The CFB series containerized asphalt mixing plant eliminates the need for packaging, allowing easy transportation, and ensuring convenience and speed.

Foundation-Free

Containerized design, CFB series containerized batching plant main building without foundation, quick installation and disassembly

BV Classification Society Certification

Certified by BV Classification Society, ensuring safety and reliability

German Screening Technology

The vibration screening technology with a 110-year history originating from Germany is characterized by efficient screening, low energy consumption, and durability

Dust Emission <20mg/Nm³

Dual-stage dust collector, dust emission in exhaust <20mg/Nm³, environmentally-friendly

Safety Interlock Device

The built-in staircase and safety interlock device provide excellent protection for the personal safety of maintenance operators

High Resale Value

Internationally renowned brand components within the container minimize wear and tear and ensure a long service life, maintaining a high resale value

Containrized Asphalt Mixing Plant Components

1. Cold Aggregate Feeding System

① Controlled by a frequency converter, allowing stepless variable speed adjustment to enhance efficiency and reduce energy consumption;

② Equipped with sidewall belt to prevent aggregate spillage;

③ Features a sand bin moisture-proof device and bin wall vibrators to ensure a smooth material discharge process and prevent bin blockage;

④ Each feeding belt's output can be individually and automatically adjusted, ensuring precise cold aggregate batching;

⑤ Automatic aggregate shortage alarms are used for enhanced efficiency;

⑥ Emergency stop pull switch to prevent further damage.

2. Drying System

① Original patented design imported, aggregates zoning heating for high heating efficiency;

② Equipped with an automatic lubrication device to reduce labor costs;

③ Riding rings are made of highly wear-resistant materials for longer service life;

④ Rock wool insulation equipped to prevent heat loss.

3. Aggregates Elevating System

① Double pitch roller chain is made of wear-resistant material, sturdy and durable;

② Hoppers come with wear-resistant edge;

③ Inlet and outlet come with special wear-resistant device;

④ Driven by gear motor with brake, more reliable and precise;

⑤ Anti-reverse device ensures smooth running;

⑥ Sealed design with perfect air tightness, no dust leakage;

⑦ Manhole and adjustment device at bottom, easy for installation and maintenance.

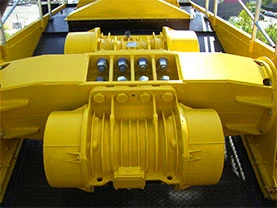

4. Vibrating and Screening System

① Vibrating screen technology originating from Germany with 110 years of history;

② Driven by two vibration motors, preventing resonance, with adjustable amplitude and frequency;

③ Equipped with highly wear-resistant screening plates to prevent aggregate mixing;

④ Specially designed feed chute, wear-resistant, and minimal noise;

⑤ Wire-meshes are made of special spring steel with anti-wear property.

5. Hot Aggregate Temporary Storage System

① Equipped with capacitive continuous level sensors to ensure high-precision measurement;

② Includes a 100mm thick rock wool insulation layer to prevent heat loss;

③ Equipped with a bypass hopper.

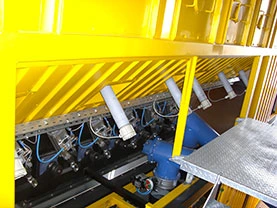

6. Weighing and Mixing System

① Each system is equipped with a weighing sensor to achieve precise measurement, ensuring accurate proportioning;

② Three-dimensional mixing, with aggregates flipping vertically, results in a more uniform mixing;

③ Swiss-formulated wear-resistant materials and multiple protective measures contribute to a long service life;

④ European technology mixer, an efficient mixing system that reduces power consumption;

⑤ The drive motor employs an automatic lubrication system, free of maintenance.

7. Finished Products Storage System

① Bottom-type finished products storage bin is convenient for discharging and transportation;

② Insulation device is equipped to ensure the asphalt quality.

8. Dust Collecting System

① Adopted a two-stage dust collecting system: the first stage employs gravity dust collector and the second stage utilizes reverse-air bag-house dust collector, ensuring high dust-collecting efficiency;

② The dust collecting system is located on the upper of the mixing tower, saving ground area;

③ The two-stage dust collecting system achieves a dust emission of ≤20 mg/Nm³, which is lower than the international industrial facility dust emission average of 30 mg/Nm³;

④ Equipped with a recycled filler storage container to minimize pollution.

9. Control System

① Containerized control room is sound-proof and heat-proof, providing comfortable environment;

② Advanced control system ensures accurate and fast operation;

③ Electrical components, including switch cabinets, circuit breakers, PLC, cables, buttons, etc., are all from well-known brands, ensuring safety and reliability;

④ Easily switch between automatic, semi-automatic, and manual modes at any time, providing simple and user-friendly operation.

How to Install CFB Series Containerized Asphalt Mixing Plant?

Related Equipment

Recommended articles

400+ Mixing Plants Exported

10 Design Patents

CCMA Director

Plant Exporter

Your inquiry will be replied within 24 hours.

[No form id or name provided!]Related Equipment

Vertical Bitumen Tank

Vertical Bitumen Tank

- Model: 35 ~ 80

- Capacity: 35 ~ 80m³

- Highlights:

1. Vertical layout, minimal footprint;

2. Corrosion-resistant and durable tank body;

3. Equipped with heating and temperature control systems;

4. Convenient and safe for transportation and installation;

Introduction to Vertical Bitumen Tank

Vertical bitumen tank is primarily used for storing and preheating bitumen, ensuring smooth application in road construction, pavement repairs, and other related projects. It plays a crucial role in activities such as preparing hot mix asphalt (HMA), surface sealing projects, and asphalt patching. Furthermore, its vital contribution to road construction and maintenance should not be overlooked. By effectively storing and preheating bitumen, it ensures the quality and flowability of bitumen during road construction, providing support for continuous and efficient construction.

Model and Parameter

| Model | 35 | 40 | 50 | 80 |

|---|---|---|---|---|

| Dimensions (mm) | 11770*2300*2300 | 11770*2300*2300 | 10050*3150*3150 | 11500*3500*3500 |

| Insulation Material | Rock Wool 80K | Rock Wool 80K | Rock Wool 80K | Rock Wool 80K |

| Insulation Thickness (mm) | 100 | 50 | 100 | 100 |

| Weight (kg) | 8000 | 8000 | 9000 | 11000 |

| Heating Method | Electric Heating, Thermal Oil Heating | |||

| Standard Accessories: | ||||

| Level Indicator | Electronic | Electronic | Electronic | Electronic |

| Thermometer | Mechanical/Electronic | Mechanical/Electronic | Mechanical/Electronic | Mechanical/Electronic |

| Ladder | Available | Available | Available | Available |

| Platform | Available | Available | Available | Available |

| Manhole | Available | Available | Available | Available |

| Mixer(kW) | 15 | 15 | 15 | 15 |

| Optional Accessories: | ||||

| Pre-assembled Pipeline | As Required | As Required | As Required | As Required |

| Valves and Accessories | As Required | As Required | As Required | As Required |

| *More models can be customized according to user requirements. | ||||

Main Features of Vertical Bitumen Tank

1. Structure and Design

The tank adopts a vertical design, maximizing the storage capacity of bitumen while minimizing ground space usage. Its rational structural layout allows for increased flexibility within confined construction sites.

2. Tank Material

High-quality metal materials, such as carbon steel or stainless steel, are employed to ensure the tank possesses excellent corrosion resistance and durability. This material selection ensures the stability and reliability of the vertical asphalt tank for long-term use.

3. Heating System

Equipped with an advanced heating system, often supporting multiple energy sources, including thermal oil or electricity. This ensures that bitumen maintains the appropriate temperature during storage, facilitating smooth pumping and application on roads when needed.

4. Temperature Control System

To ensure bitumen maintains the correct temperature, our vertical asphalt tanks typically come equipped with a temperature control system. This system monitors and adjusts temperatures to maintain the viscosity and flowability of bitumen.

5. Safety

Safety is prioritized in the design, including explosion-proof devices, over-temperature protection, and leak prevention systems. These features minimize accident risks, ensuring stable equipment operation and the safety of personnel.

6. Transportation and Installation

Due to its vertical design, vertical bitumen tanks are generally more convenient for transportation and installation. They can adapt more flexibly to different construction sites and space constraints.

Your inquiry will be replied within 24 hours.

[No form id or name provided!]LiaoYuan Road Construction Machinery Co., Ltd.

LiaoYuan Road Construction Machinery Co., Ltd.

LiaoYuan Road Construction Machinery Co., Ltd.(LYROAD Machinery, or briefly LYROAD) was established in 2004 and has since focused on the research, development, manufacture, and sale of asphalt mix production equipment. The course of nearly 20 years has witnessed LYROAD Machinery has grown into a reputable manufacturer and supplier of asphalt plants and concrete plants worldwide. We are proud to be widely recognized as an expert in asphalt plant custom manufacturing.

LiaoYuan Road Construction Machinery Co., Ltd., now a subsidiary of ACE Group (Asian Construction Equipment Group Co., Ltd.), re-positioned itself as a professional building material production solutions provider several years ago. We not only accept customization requirements but offer one-stop integrated solutions to the mixing equipment and its auxiliary devices to customers all over the world. LYROAD Machinery's coverage includes batch mix asphalt plants, drum mix asphalt plants, mobile asphalt plants, concrete mixing plants, wet mix macadam plants, dry mix mortar plants, as well as bitumen melting machines, bitumen emulsion plants, asphalt rubber plant, etc., with annual output value reaching 500 million RMB. So far, over 80 countries have the presence of LYROAD's equipment, gaining a great reputation relying on strict quality control, sound technical support, and mature customer relationship management.

In the future, LYROAD Machinery will continue to provide value to the global infrastructure construction industry through client-oriented equipment manufacturing and export. We sincerely welcome new and old customers to visit our company and our factories, and let's work together to build a better world.

Contact Us

Address: Wanli Industrial Park, Xuchang, Henan, China

Mobile (WhatsApp): +86-177-3700-0591

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.