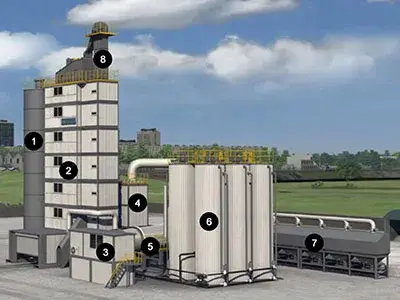

Asphalt Batch Mixing Plant JNW Series

- Model: JNW180 ~ JNW340

- Product Capacity: 180 t/h ~ 340 t/h

- Highlights:Stationary, batch mixing, precise batching;

Ecological, minimal energy consumption, maximum efficiency.

Brief Introduction

Asphalt Batch Mixing Plant JNW Series a new type batch mixing asphalt plant launched by LYROAD Machinery in late 2016. JNW Series adopts many self-developed patents and has outstanding improvements in weighing accuracy, productivity, material and fuel conservation and pollutant elimination. JNW Series asphalt plant's output is 160 ~ 400tph, fit for road construction projects that has special requirements for asphalt quality, energy conservation and environmental protection.

Product Parameters

| Model | Capacity | Mixer Size |

Diesel Consumption; |

Static |

| JNW180 | 180 t/h | 2000kg | 6~6.5kg/t | Agg.: ±0.5% Filler: ±0.25% Bitumen: ±0.25% |

| JNW220 | 220 t/h | 2500kg | 6~6.5kg/t | |

| JNW260 | 260 t/h | 3000kg | 6~6.5kg/t | |

| JNW340 | 340 t/h | 4000kg | 6~6.5kg/t |

Main Features

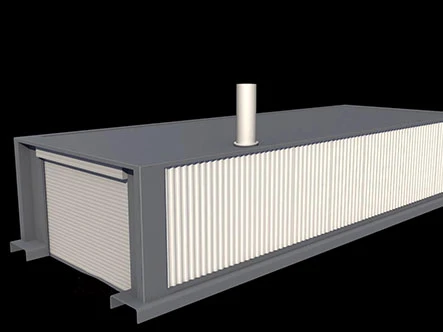

1. Patent structure, whole production process is fully enclosed; aggregate feeder, belt conveyor, loading chamber and mixing tower are all enclosed; minimal dust and pollutant emission; safe and clean;

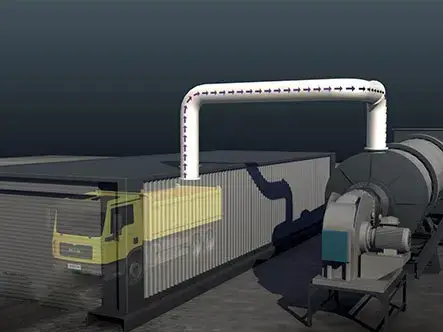

2. Activate carbon devices are installed on bitumen tanks to absorb asphalt fume; asphalt fume generated in truck loading chamber is collected and circulate to drying drum and burn out, eliminating asphalt fume and other hazardous gas emission;

3. Separated hot aggregate bins, intelligent and precise control over cold aggregate feeding and hot aggregate storage; no overflowed hot aggregate during production, no redundant hot aggregate after production; eliminating waste of aggregate and fuel;

4.Patent "synchronized decrement" weighing method, eliminating the weighing error caused by the “flash materials”; dynamic weighing accuracy: aggregate and filler<1%, bitumen<0.8%; static weighing accuracy: aggregate±0.5%, filler and bitumen±0.25%;

5. Multi-stage dust collecting system, 1 gravitational dust collector and 2 bag house dust collectors, better dust removal effect;

6. Batch cycle time is reduced to 40 seconds, the whole plant is more efficient and 15% more productive than that of same model batch mixing plant.

Structure

1. Filler Silo

Equipped with arch broken device, ensuring continuous filler supply.

2. Mixing Tower

Vibrating screen has 5-tier mesh, hot aggregate are classified into 5 particle size and stored in separate bins; screening and grading are more precise; "low flow + decrement weighing" measurement, more accurate

3.Control Room

SIEMENS electronic elements, PLC, EMERSON inverter, Mettler-Tolerdo sensor.

4.Dust Filtration

Two stage dust filtration:

Primary:cyclone dust filter x1, gravitational filtration; collect and recycle the large particle dusts in the hot air from drying drum;

Secondary: bag house filter x2; the small bag filter removes the dust in the aggregate feeder and belt conveyors; the big one removes dust in drying drum and mixing tower. NOMEX bag, sturdy and endurable, better filtration effect.

5.Drying Drum

Centralized automatic lubricating system, optimized structure.

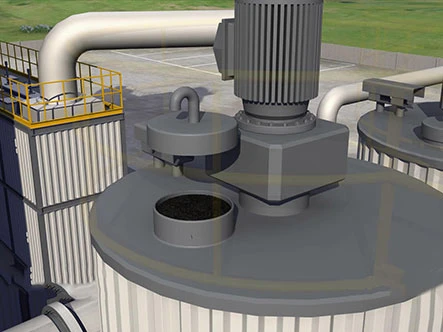

6.Bitumen Tank

Hot oil/electric warming, with activated carbon asphalt fume absorption device.

7.Cold Aggregate Feeder

Enclosed structure, with dust collecting cover.

8.Filler Elevator

Chain hopper elevator, easy for maintenance; seamless structure, no dust leakage, sturdy and durable.

Component Details

Enclosed mixing tower

Enclosed aggregate feeder

Enclosed belt conveyor

Enclosed truck loading chamber

Two (2)bag house filter

Activate carbon device (absorb asphalt fume)

Asphalt fume in loading chamber drafted to drying drum and burnt

Control Room